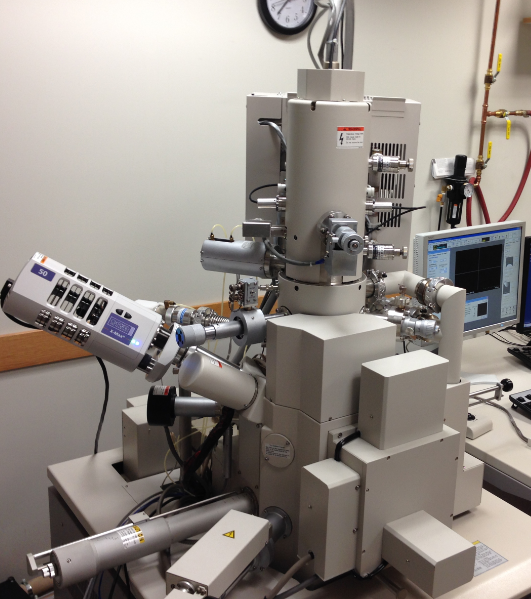

Guidance to use FESEM/EDS for research

Guidance to use FESEM/EDS for research after new installation

- Resident who wants to use new FESEM must operate in regular working hour 8a-5p weekday.

- Qualified user can operate and reserve time through Google calendar or in-lab calendar.

- Non-qualified user must reserve time under the supervision by Dr. Fan or quanlified users. Non-qualified user should check the assisting hour when reserving SEM time.

- To be qualified user for general SEM, you must have at least two hour practice session under supervision and pass test with standard gold particle specimen at 50-100k magnification. Test must be a separate day than training.

Guidance to sample preparation for SE imaging, EDS analysis

- At SEM high vaccum mode, no volatile or reactive chemicals, fluid, oils, grease, loose particles, easily degassing, or large sized. Wear gloves when handle specimen stubs.

- If possible, specimens should be cleaned by isopropanol in sonication bath for 2-5 mins and dry.

- If you use gold sputter, try 5-10 seconds coating. Longer time may build up visible gold particles under >20 k magnification.

Guidance to data saving and transferring from FESEM/EDS

- Save to the folder by operator’s name under mapped drive Z:\ . The drive is physically in EDS computer hard drive. Randomly saved images in SU6600 hard drive will be deleted periodically.

- Save images, spectrum, EDS project, and EDS report from EDS computer

- Save to the folder by operator’s name under drive D (Data):\ SU6600 images\

- Image files or folder randomly saved on desktop or SEM computer may be deleted without any warning.

- Copy images and data files from EDS computer only. Do not plug USB flash drive on SU6600 computer.

- Use lab provided USB drive only.

Save images from SU6600 microscope

Copy data files

Guidance to BSE, ESED, VP mode, and STEM.

Contact Dr. Fan to arrange one-on-one training.

Qualified User

To be qualified user for general SEM, you must have at least two hour practice session under supervision and pass test with standard gold particle specimen at 50-100k magnification. Test must be a separate day than training.

Qualified user can operate and reserve time through Google calendar or in-lab calendar.

Non-qualified user must reserve time through in-lab calendar and operate under the supervision of Dr. Fan or Claire at working hours only. Non-qualified user should check the assisting hour when reserving SEM time.

Qualified user list (as of 5/1/2021)

- Reem

- Peixi

- Aziz

- Leo (Kim J)

- Nayrouz Talua

- Ashraf

- Alayad

- Lena

- Terewat(Sun)

- Hossam

- Saeed

- Ryan

- Redwan

- MahaQ

- Aasem

- Maria

- Supontep

- Rasha

- Hessa

- Waad

- Haidar

- Chayanit

- Abdu 2

- Sunporn

- Hussain

- Guna

- Kinara

- Asmaa

- Jeenarak

- Dania

- Walid

- Khaled

- Homoud

- Megha

- Mike

- Bebi

- Muad

- Lina

- Nilay

Training Process

Biomaterials lab faculty and staff can offer introduction training, practice training and advanced training for different level of users.

Introduction training is designed for any new user who has no previous experience in SEM. It contains two parts one hour lecture about the principle of SEM and two hours hand-on training on SEM operation. After this training, the trainee should have the basic knowledge of SEM principle, equipment safety, equipment configuration, training procedure, sample loading, and basic operation procedures for secondary electron images. Normally this training is in a small grooup of 4-5 people.

Practice training is designed for any new user who has basic knowledge of SEM or has previous experiment in operating other model of SEM, FESEM, and EDS. It is an hands-on operation practice under the supervision of lab manager or faculty. Each training session is two hours by appointment. First two hours must be supervised by lab manager. Additional training hours could be accompanied by any qualified student user. The purpose of this training is to help user grasp the basic skills of how to operate SU6600 in safely, how to prepare specimens for SEM, and how to acquire high quantity SE images and basic EDS in a good practice. Normally this training is one on one basis.

Advanced training is designed for any user who has learned basic knowledge of SEM and has enough experience in operating SU6600. The purpose of this training is to explore the functionality of SU6600. It contains backscattering image (BSE), environmental secondary electron image (ESED), variable pressure (VP-SEM), elemental mapping and qualitative analysis (EDS) and scanning transmission electron image (STEM).Normally this training is one on one basis.

Advanced sample preparation training is designed for any user has some SEM experience but needs to handle fragile specimen, thin film, nanoparticles and biological specimen. Normally this training is one on one basis.

Testing Process for Qualified users

Testing is to ensure users have good operation skills to acquire publishable images and data independently and keep equipment safe. To be a qualified user for general SEM, one must have at least two hour practice session under supervision and pass test with standard gold particle specimen at 50-100k magnification or research specimen in his/her project. Test must be at a separate day other than training day. Test is operation on standard gold particle specimen at 50-100k magnification or one research specimen in his/her project. Demonstrating insufficient knowledge of SEM operation, dangerous operation and sloppy research practice will not be recognized as qualified user.

Qualified user should:

- know in-depth SEM/EDS principles,

- understand the configuration of SU6600, vacuum, electricity system.

- demonstrate good operation practice, and know emergency procedure,

- can achieve high quality publishable SE image,

- can explain and supervise operation procedure to new users.

Average practice time for new user is four hours. We encourage more practice time before testing. First two hour practice training must be supervised by Claire or Dr. Fan. Additional hours of practice can be supervised by any qualified user. Previous experience in other model of SEM could shorten practice time to two hours.

Qualified user is mainly working on high vacuum SE mode at a minimal acceptable standard. Further training should be required to ensure user operating other detectors including EDS, BSE, ESED and STEM.

Basic knowledge of SEM

The website of Austrilian M&M Research Facility is a very good resource to learn the mechanism and operation principle of SEM and EDS.

SOP for scanning electron microscope

Potential harzard in operation

- High pressure compressed gas.

- High voltage and electromegnetic field.

- Eye fatigue.

- Resident who wants assistant in using SU6600 FESEM must operate in regular working hour 8a-5p working day.

- Non-qualified user must reserve time through in-lab calendar and operate with Dr. Fan or Claire or qualified user. Non-qualified user should check the available assisting hours when reserving SEM time.

- Qualified user can reserve SEM time through Google calendar or in-lab calendar.

- Each session booked for 8a-5p weekday is maximum two hours. If there is other user waiting for SEM after your session, you must finish your session asap.

- After hour use (5p-8a working days and holidays) is first-come-first-serve basis and can be reserved 24 hour in advance.

- If you show up fifteen minutes (15 mins) late for your session, your reservation is automatically cancelled and other user can use this SEM time.

- No ghost booking. Any reserved time with NO SHOW (according to logbook) and no canellation will be recorded as one ghost booking. Three times of ghost booking will be noticed to residents' PI and may incur depriving of SEM user.

- Equipment maintenance has higher prioriy in machine time.

Reservation and user time

- Check the status of FESEM. Hitachi SU6600 is equipped with ZrO/W field emission electron tip running at 1700 K all the time.

- The filament indicator [Fil] should be on red illumination in normal condition.

- High voltage indicator [HV] should be dimmed.

- Sample exchange chamber show two green indicator [close] and [evac].

- All front panel LEDs should be green, HV tank LEDs should be all in red.

- Mount specimen on proper stub with carbon conductive tape.

- Measure specimen standard height with height ruler.

- Always wear gloves to touch a specimen for SEM analysis. Finger print is a major reason causing surface chanrging and blurred image.

- [Air] the exchange chamber,

- Open specimen exchange chamber, load specimen on specimen deliver rod,

- [Evac] the exchange chamber,

- [Open] exchange chamber valve,

- send specimen in the spring track of stage, unlock specimen,

- pull out specimen deliver rod.

- [Close] specimen exchange chamber valve

- Enter the size/height in to SEM control.

- Click [home] to send stage under column.

- Click [ON] button to turn on beam.

- Perform beam alignment and appurture alignment.

- Acquire images or specturm and save data to your own folder.

- Click [OFF] button to turn off beam

- Remove specimen holder from chamber:

- Click [exc] button to move stage to exchange position

- [Open] exchange chamber valve,

- Insert specimen deliver rod in unlock position, pull out specimen out in lock position,

- Pull out specimen fully into exchange chamber,

- [Close] exchange chamber valve

- [Air] the exchange chamber,

- open sample exchange chamber, take stub out

- [Evac] the exchange chamber, if you have VP-SEM mode, switch to SEM mode.

- Clean bench, leave stub holder, tools and standard samples in desiccator

- Turn off monitors, not shutdown computers.

- Sign off logbook.

- For non-conductive specimen observation. Au-Pd sputter coating is suggested. For SEM high resolution observation, coat 15s. For porous structure, longer sputter coating time and different coating angle will help.

- For EDS analysis, carbon coating is strongly suggested. Au sputter coating is also acceptable for simple elemental analysis.

Preparation:

Specimen loading:

Imaging

Specimen unloading

Finishing

Conductive Coating:

EMERGENCY SHUTDOWN PROCEDURE

- Only used in case of fire on the Hitachi FESEM machine.

- Use the red emergency shutdown button on the front panel under column to cut off all electricity.

- This instrument is connected to UPS backup batteries. Switch off power supply will not cut off power to FESEM.

- EDS computer and Oxford Instrument processors are powered directly from regular generator line from the east side of the wall.

SEM Reservation

- Only a qualified user can reserve SEM time independently.

- Reservation is for the convenience of scheduling the machine time only. Without reservation, it runs first-come-first-serve.

- Any no show 15 mins or later will automatically void the reversed session. Then it will become a first-come-first-serve basis.

- Please do not reserve more than two consecutive days and each reserved session cannot be over 4 hours from 9 am -5 pm, M-F.

- Please do not reserve a time if you actually do not intend to use the machine.

SEM Operation Demo Videos

Please find in Teams and Yammer Channel.

Tips:

- Apply proper conductive tape or silver paste to improve surface conductivity.

- Do not use Duco cement to mount samples on stub. This type of MMA based cement may release voltile monomer. Using cyanoacrylate, low melting point glue, or Ted Pella crystal wax.

- Lower kV provides more informtion on surface. Higher kV may reveal subsurface (>20nm) structure.