At the BU GSDM dental biomaterials laboratory, over 140 shared instruments/tools are available for education and research. The instruments cover a wide range of applications in dental materials research including tissue culture, specimen section and polishing, chemical processing, polymer synthesis, ceramic processing, computerized dentistry, dental material processing, color testing, solution testing, surface analysis, imaging, elemental analysis, mechanical testing, and others. Laboratory facilities located at R5 are open for residents and faculty. The instruments are well-maintained and ready for use but proper training is required for access those instruments.

Instrument Overview

Category I: Materials Synthesis and Manufacture

Instruments used for simple chemical synthesis, ceramic sintering, heat treatment, press, monomer infiltration and polymerization.

- Wet chemistry: Glassware, vacuum desiccator, magnetic stirrer, hotplate, pH meter/ion analyzer, glassware, filter, refrigerator, microwave, thermal couple meter, thermometer, vacuum gauge, UV light source, desiccator, vacuum desiccator.

- Furnaces: 5x Dental ceramic vacuum furnace (up to 1200oC), 2x Thermolyne tube furnace (800-1700oC), 4x Vulcan box furnace (50-1100 oC), 2x Vita Zirconia furnace (1300- 1600oC), 2 Thermolyne regular furnace (100-1093 oC, one in X building), Zircar (500-1600oC)

- Ovens: Incubator (37oC), General oven (RT-160oC), burn out oven (200-500oC), VWR vacuum oven.

- Isopress: 1x 50 ton, and 2x 12 ton hydraulic press units

- Resin infiltration: 0.4 Torr vacuum, ~200 mL infiltration volume

- Light curing unit: UV light curing, Blue light curing unit, pressurized curing pot

Category II: Materials Processing

Instruments used to process raw materials for research use via physical processes.

- Polishing machine: Buehler EcoMet 250/AutoMet 250; RedWing; Model trimmer

- Wear machine: motor driven 2- and 3-body brushing wear tester

- Fatigue machine: pneumatically driven, 8 single unit medium (x7.86), 2 large five unit assembly (x 21.84), 2 medium five unit assembly (×7.86) and 2 X-small five unit assembly (x 1.364).

- Sectioning machine: Buehler Isomet 5000 linear precision saw, 11-180 low speed saw, with diamond blade.

- Sonicator: 4x Ultrasonicator bath, 2x Ultrasonicator probe processor

- Bur cutting tester: home made by Pober.

- Dental material processer: Light curing unit, 8x, hand piece station, Allure Bleach light station, Oral plasma generator, denture pressurized curing oven

- CAD/CAM: Object scanner (Eos, Eos Blue, Omni, Blue light, Lava Chairside Oral scanner), Milling machine (Sorina inLab MC XL, inLab MC, CEREC MC XL, inLab, CEREC 3)

- Separation: bench-top centrifuge

- Mixer: motor mixer, Rotary mixer

- Thermocycling machine

- Sandblaster machine: PrepStar, Renfer Basic sand blaster

- Ball milling machine: Jar miller

Category III: Physical properties analysis

Instruments used to test physical properties of materials and output data.

- Microstructure imaging: Field emission electron microscope (FESEM) with energy dispersive spectrometer (EDS), Optical microscope including stereomicroscope, 3D digital microscope, phase contrast microscope, bright field microscope.

- Mechanical tester: Universal Mechanical Testing Machine, Microhardness tester

- Color testing: Colorimeter, i5 Spectrophotometer, Digital shade guide (Vita Easyshade, Vita Easyshade Compact), Viewing booth, Gloss meter.

- Spectrometer: FTIR spectrometer, i5 spectrophotometer.

- Weight measurement: Balance, Scale.

- Dimension measurement: Micrometer, Caliper, Profilometer.

- Other physical properties tester: Radiometer, tachometer, multimeter (Volt-Ohm meter), digital camera.

- Test apparatus: Achemedes density tester, thermal shock, creep tester with temperature control

Category IV: Tissue culture instruments

Instruments used to perform cell culture, cell biology and molecular biology assay.

- Cell culture essential equipment: Class IIA/B3 biological safety cabinet, autoclave, CO2 controlled incubator, liquid nitrogen dewer, water bath, -80° C freezer, -20° C freezer, 4° C refrigerator, tissue culture centrifuge, electronic cell counter.

- Bio Lab instrument: Water ultra-purification system, high speed centrifuge, low speed shaker, UV-Vis spectrophotometer, UV transilluminator, balance, pH meter, and stirrer.

- Microscopes: Tissue culture inverted microscope, reflected-light differential interference contrast microscope, bright light microscope.

- Molecular biology: Electrophoretic gel system, Bio-Rad power supply, electrophorectic systems, pressure blotter, slot-blot apparatus, PCR machine.

Category V: Machining Tools

Instruments used to cut, trim, or drill hard materials into desired geometry. Please note most machinery requires special training and students are not allowed to operate for safety reasons.

- Computer numerical controlled (CNC) machine, Compact 5 (EMCO Maier, Austria)

- Unimat lathe (EMCO Maier, Austria)

- Drill press, milling machine, band saw, biopsy saw, air abrasion units, casting machines,

- Gypsum trimmers, disc saw cutter.

- Soldering machine: Soldering station, Thermal couple welder.

Specifications of major testing instruments

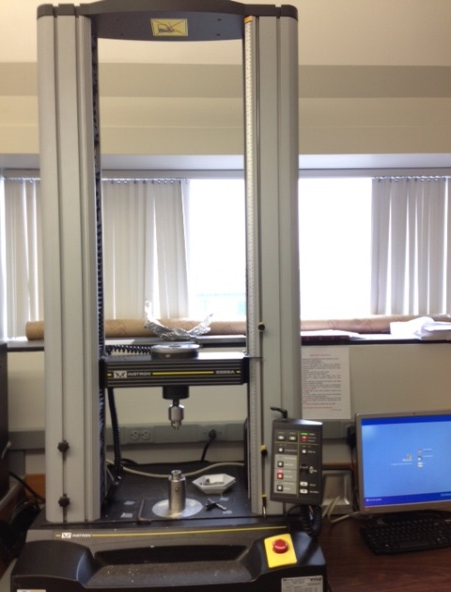

Name/Model: Universal Testing Machine Instron 5566A

Manufacturer: Instron, Norwood, MA

Electromechanical load frames are designed to apply a load to a test specimen via the moving crosshead.

Software version: Bluehill 3,0

Tension, Compression, Tension Creep Relaxation, Compression Creep Relaxation, Tension Profile, Compression Profile,

Peel/Tear/Friction, Flexure, Metals (Yield), Flexure Creep Relaxation

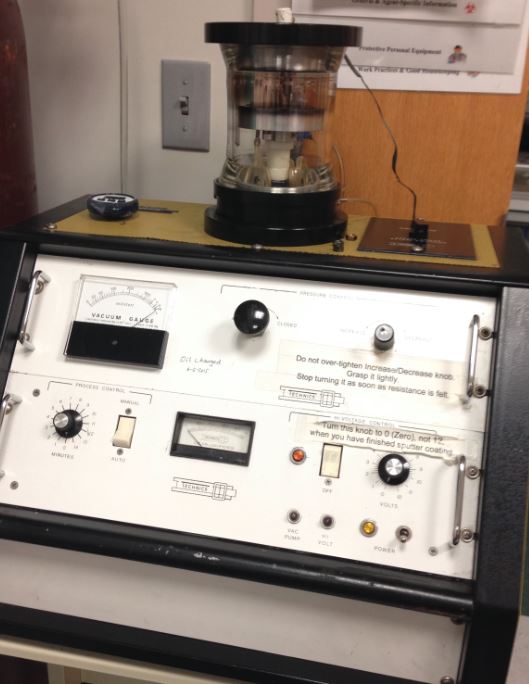

Name: Sputter coater Model: Technics Hummer V

Manufacturer: Anatech Ltd, Springfield, VA (now it is Anatech USA, SPARKS, NV)

Sputter coating Au. Au/Pd (75/25)

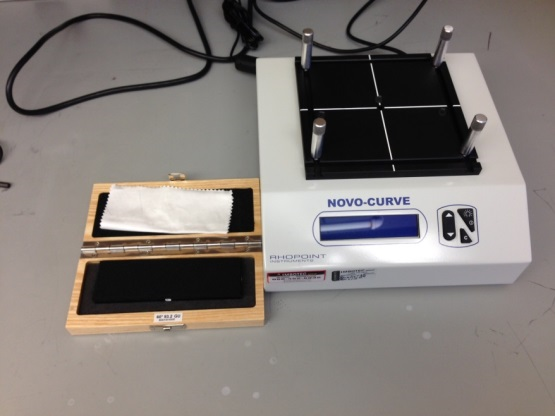

Name/Model: Gloss meter, Novo-curve

Manufacturer: Rhopoint Instruments, UK

Gloss is measured by shining a known amount of light at a surface and quantifying the reflectance. The angle of the light and the method by which the reflectance is measured are determined by the surface.

Novo-Curve is designed to measure gloss index for curved surface like teeth, pens, spoons, bottles, jewelry, etc. It follows the standard of ASTM D 523 / D 2457. It may be applied to study dental materials, such as surface polishability of composite, porcelain glazing, light reflectance and etc.

Measurement Angle: 60°, Range: 0 - 1000 GU

Name/Model: Microhardness Tester, Wilson VH 1202

Manufacturer: Buehler Ltd, Lake Bluff IL

Knoop and Vickers hardness testing.

Indentation fracture toughness.

Twoe indenter turret.

Two optical lenses: 40x, 10x.

Digital Zoom:

Load: 10, 25, 50, 100, 200, 300, 500, 1000, 2000 g

Name/Model: High-temperature sintering furnace, Zircar Hotspot 110

Manufacturer: Zicar Zirconia Inc.

programmable atmospheric high-temperature sintering furnace.

High-heat firing chamber (maximium:1600oC)

Four Molybdenum Disilicide Heating Elements

Programmable controller. Hold two programs of up to 8 segments.

Cleaning firing: Ramp to 1350 in 1 hour, Ramp to 1600 in 1 hour, Soak at 1600 for 1 hour, End

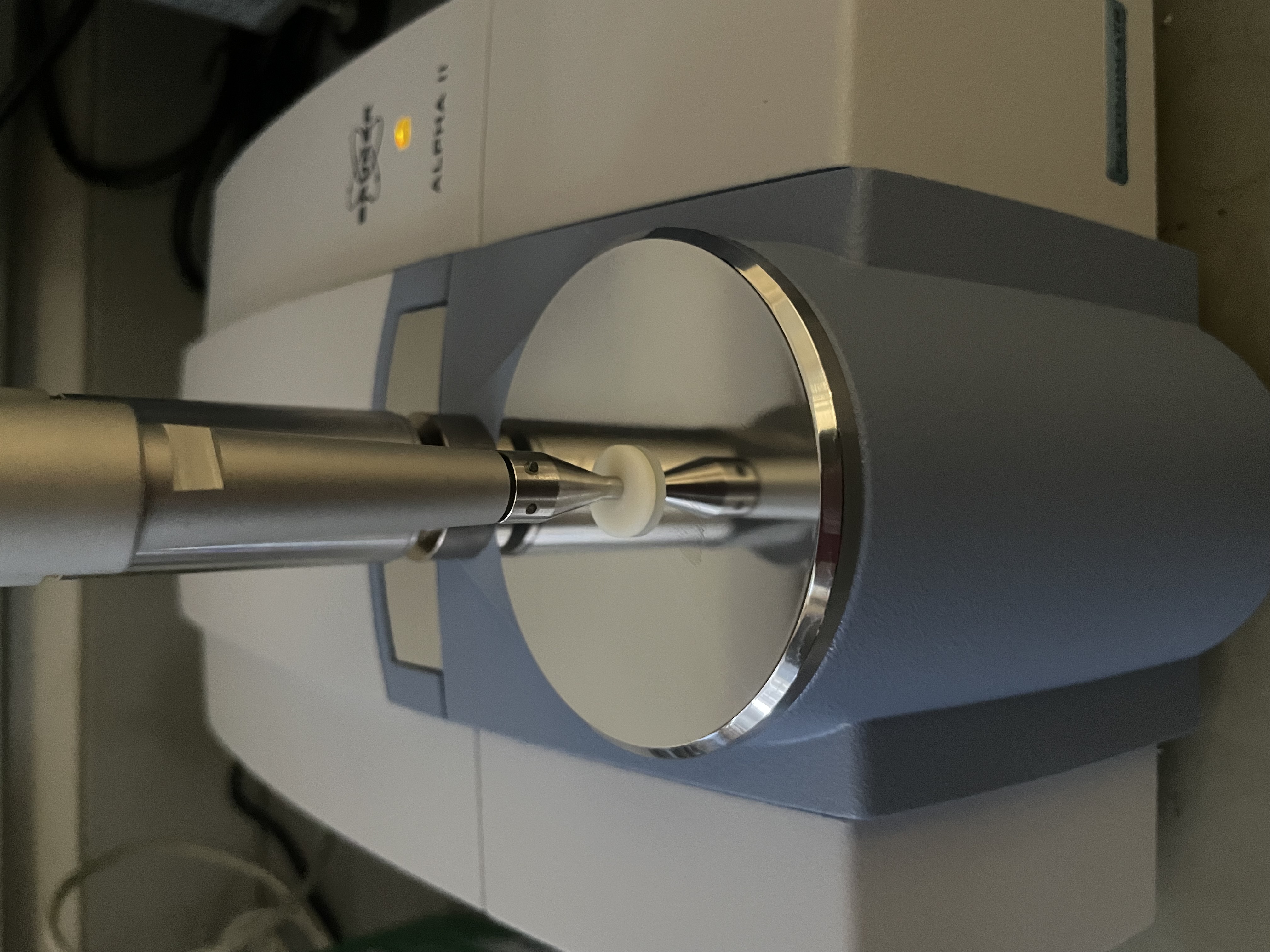

Name/Model: FTIR/Alpha II

Manufacturer: Bruker

A compact FT-IR (Fourier transform infrared spectroscopy) spectrometer

Name/Model: Vulcan Furnaces, 3-1750, 3-550, 3-130

Manufacturer: Neytech

50-1100 oC, burnout furnace, Three segments setting wihtout auto off.

Application: burnout, not recommended to use under 300oC

Note: Setting parameters of zero in ramp or temperature will neutralize that segment.

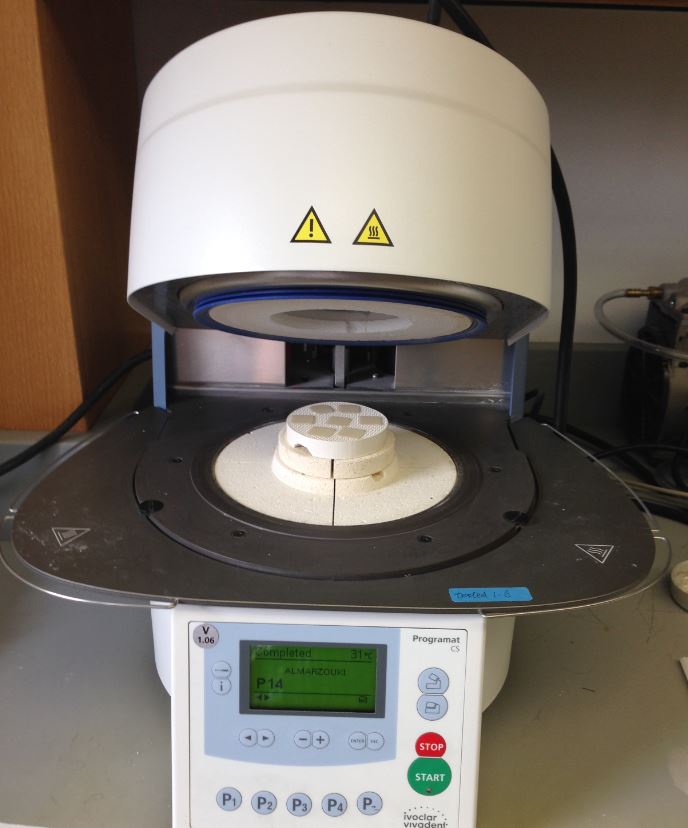

Name/Model: Programat CS Dental Furnace

Manufacturer: Ivoclar vivadent

max. 1200 oC, vacuum furnace, Two segments settings

Application: procelain sintering, e.max CAD crystallization, glazing.

Note: 1. Setting of one segment and two segment are easily messed. Make sure which one you choose in the control profile.

2. Firing to many specimens may cuase underfire and the damage on specimens cannot be fixed.

Youtube Guide 1 HOW TO USE

Name/Model: Profilometer/ SJ-201

Manufacturer: Mitutoyo, Japan

Measuring force: 0.75mN, Stylus profile: Tip radius: 5μm

Meaure parameter Ra, Rq, Ry, Rz, Rk, Rt, Rp, R3z, S, Sm, Pc, mr (c), Rpk, Rvk, Mr1, Mr2, A1, A2, Vo

Cutoff: .01, .03, .1 inch (0.25, 0.8, 2.5mm)

Z range: (-200μm to +150μm)

Application: Surface roughness measurement.

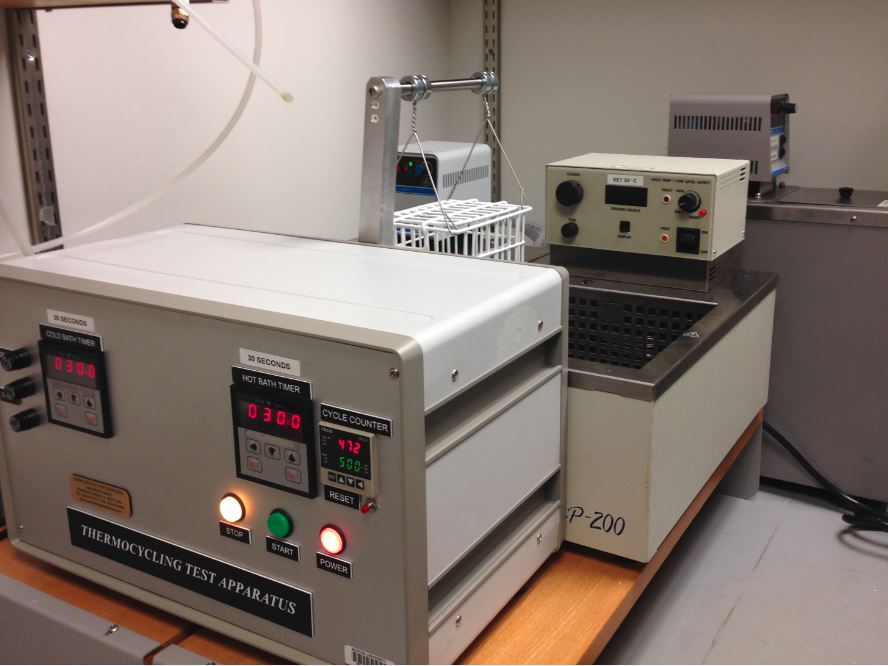

Name/Model: Thermocycling test apparatus

Manufacturer: Sabri Dental Enterprises Inc., Downers Grove, IL

Hot bath, chiller circulator, cold bath, timer controller

Application: Material thermocycling challenge. Normal setting cold bath 5C, hot bath 55C.

Note:>Limit thermal capacity. Do not load large amount of specimens.

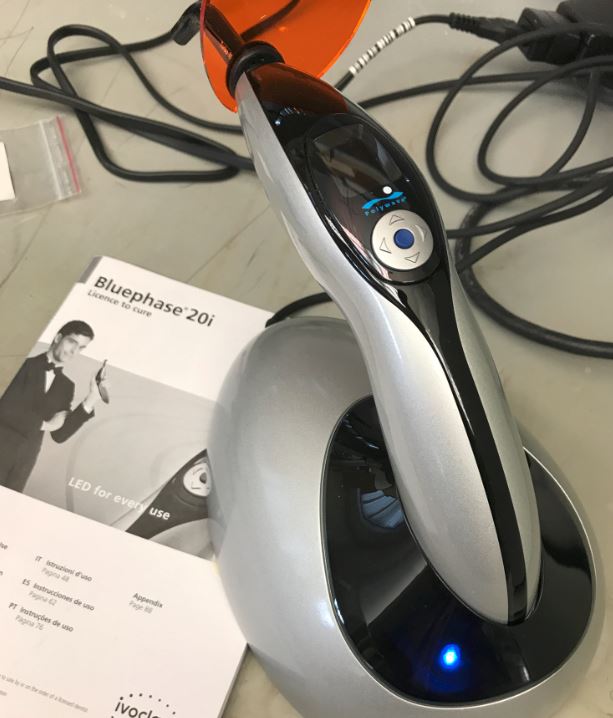

Name/Model: Curing light unit/Bluephase 20i

Manufacturer: Ivoclar Vivadent, Schaan, Liechtenstein

Turbo 2000 mW/cm2, High 1200mW/cm2, low 650mW/cm2

385-515 cm-1

Application: Photo polymerization initiattion.

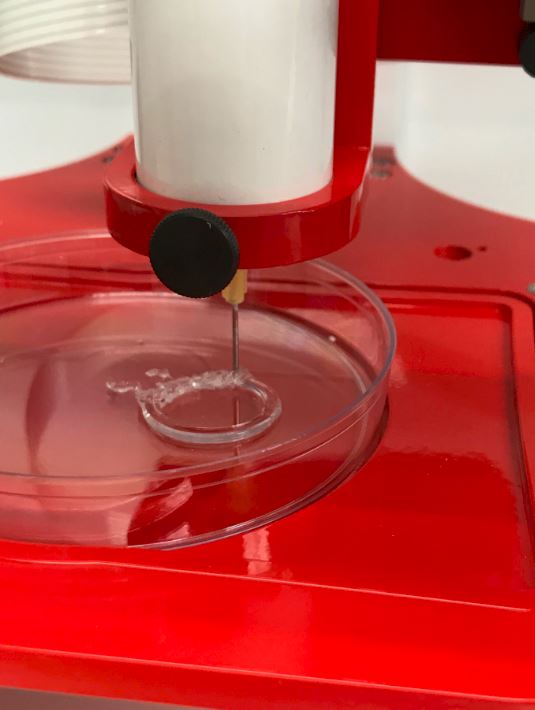

Name/Model: Bladeless Rotary Mixer/Speedmixer DAC 150.1 FVZ-K

Manufacturer: FlackTek Inc, Landrum, SC

Vacuum chamber. 0-100g mixing capacity.

Max Speed 3500 rpm.

Application: Mixing fluid/powder, powder/powder, fluid/fluid. Grinding powder.

Name/Model: IR thermal cam/ 226

Manufacturer: Fotric, Dallas TX

28x21 lens, 384x288 resolution, video and photo recording

Application: Thermal image.

Name/Model: 3D Bioprinter

Manufacturer: Allevi 2

2 channel bioprinter

Application: Rapid prototyping. Construct 3D Biomaterial Construct.

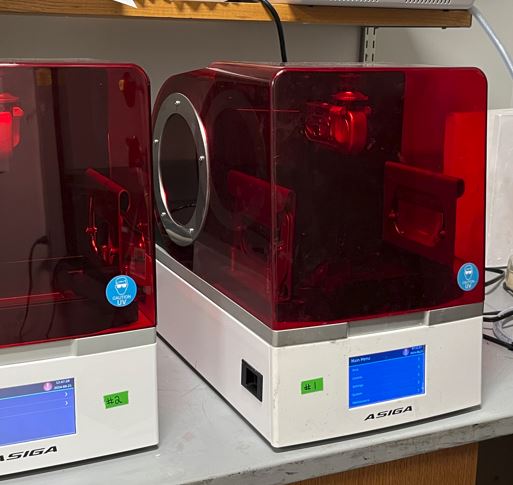

Name/Model: 3D Printer

Manufacturer: Asiga MAX UV385

DLP printer

Application: UV photocuring resin 3D printing.

Name/Model: 3D Printer

Manufacturer: SprintRay Pro 95S

DLP printer

Application: UV photocuring resin 3D printing.

Name/Model: UV photocuring unit Ottoflash G171

Manufacturer: NK-Optik GmbH

UV photocuring unit

Application: UV flashing photocuring unit with or without nitrogen.

Name/Model: 3D Digital Microscope/VHX7000N

Manufacturer: Keyence Co.

Application: Optical Imaging. max x500