Diamond Saw Section SOP

Potential harzard in operation

- Splashing debris and water.

- Moving parts may hit figer.

- Sharp objective.

- Electric shock

Check equipment and supplies

- Check the electric power of the machine. Turn the power ON. After system boots up, the first page should show up on the control panel.

- Check the water tank under the machine. Change water if it is dirty.

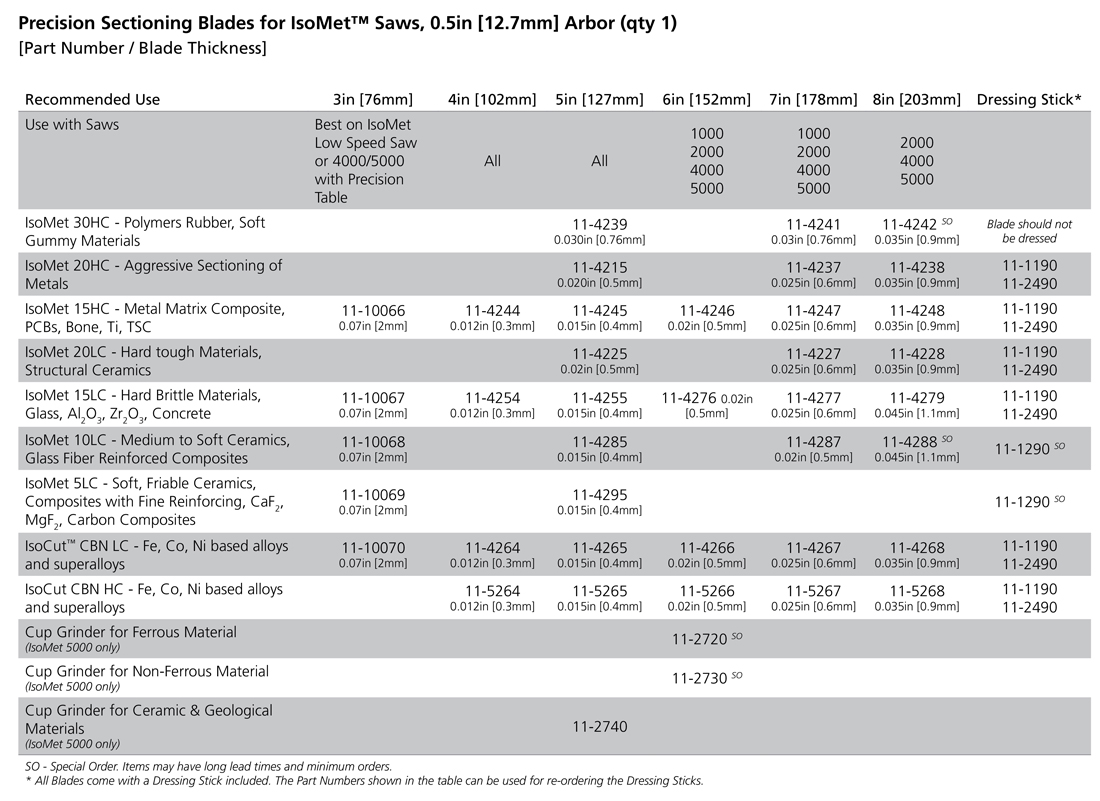

- Make sure you have known which blade you should use. If you do not need precision cut or do not know which one should choose, use generic blade on the board for practise. Read this section to choose special blade.

Preparations

- Check the blade you choose. Edge chipped or wobbled blade is not good for precision section.

- Select the proper chuck to mount your specimen.

- Mount the blade with proper flanges on blade motor fixture.

- Check the readiness of section machine. If any error messages show up, check manual or ask for help.

Manual Section/Single Section

- Align blade with your specimens. Close hood. Set zero position.

- Set feeding rate starting 8 mm/min for brittle materials (zirconia, glass) and 12 mm/min for soft material (composite, epoxy).

- Press pump motor to start water. Check water spraying on the section position of the specimen. If not adjest the spray angle.

- Press "blade motor" to start blade rotation. 2000-3000 rpm is OK.

- Press "feed motor" to start section.

- When one section finished, Press "feed motor" to stop section, then "blade motor" to stop blade rotation and "pump motor" to stop water.

- Roll back the Y-axis and adjust X-axis to next section postion by pressing X-position button.

- Repeat step 3-7 untill finish all sections in this direction.

Automatic Multiple Section

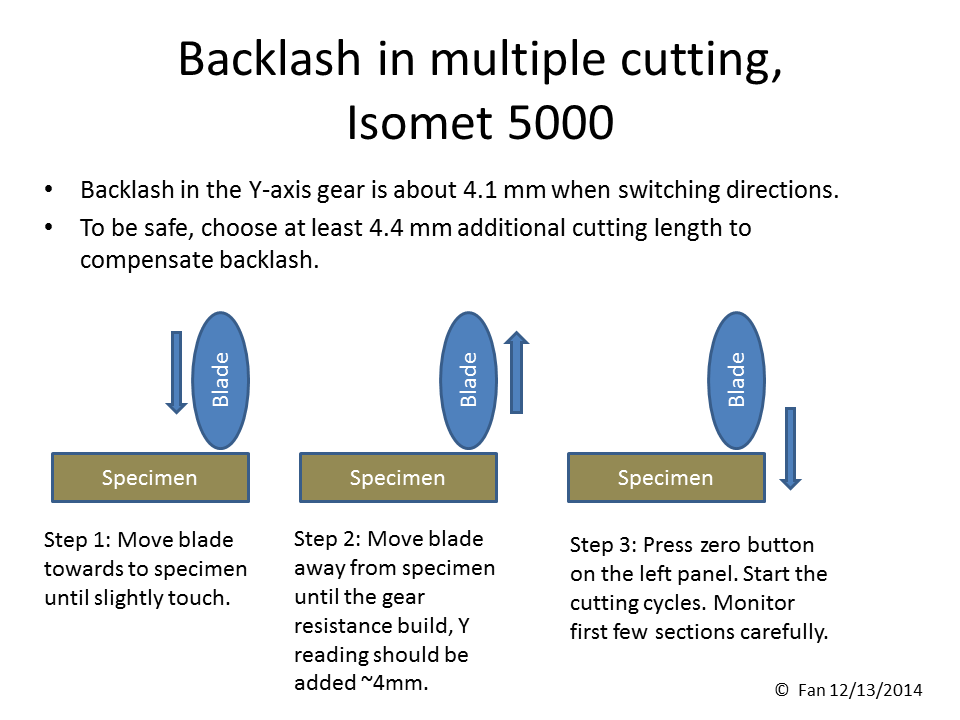

- Align blade with your specimens for datum section. Close hood. Set zero position. Notice the backlash effect.

- Set the section thickness, feed rate, cutting length and specimen numbers

- Press pump motor to start water. Check water spraying on the section position of the specimen. If not adjest the spray angle.

- Press "start cycles" to start section program.

- When the program finishes, open the hood and collect your specimens.

Finishing Up

When you are completely finished using the section machine you must do the following:

- Clean up the blade, flanges and fixture, making sure you remove the section residue.

- Put the blade, flanges and chunks on the board or the blade box. Wipe them if necessage.

- Clean the debris on the draining mesh.

- Clean the water tank, rinse with water and refill with fresh water.

- Wipe the X motor holder, and buttons with a moist towel or sponge.

- Turn off the power. Leave the hood open to prevent rusting.

- Fill the logbook.

Wrong doings which may cause of the machine damage:

- Flange mounted flipped - flange has direction

- Too small flange, or one flange - flanges come in pair,

- Wrong type of blade - check the table to select matched blade for material to section

- Lack of coolant - add more water

- Wrong direction of blade - facing the label outwards

Trouble shoote:

- Blade pinched - blade need to be dressed.

- Cut slot is not straight - the blade may be wobbling. Check flatness of blade and secure the mounting screw. Unfit flange (wrong size or wrong direction) may cause wobbling.

- X table cannot move further - X-table have travel limit of 2 inches.

- X table moves too short - need do "hard home", press and hold button middle zero key in the arrow buttons for 10 seconds.

- Loud noise from water pump - check water level and bent of the pipe. Clean the cooling water, there may be section debris or small specimens in the pipe.

- Feed motor moves backwards - you may accidentally pressed the hard home button (middle zero key in the arrow buttons). You need to take off specimen and balde, wait until finishing the hard home procedures.

How to choose wafer blade?

Diamond blades come with different particle size and density. High Concentration (HC) for general laboratory use, either low or high saw’s speed. Low concentration (LC) for sectioning hard and brittle materials, such as ceramics, silicon, glass, minerals. We have several Buhler blades for general use and special use. Read carefully before choosing blade. This chart is very helpful as a reference.

Tips:

- Isomet 5000 has strong backlash during mutiple sectioning. Please read carfully about this. Wrong setting may cause blade and/or motor damage.

- When you feel the blade is blunt, it is normally smeared by soft materials. Please cut dressing block to clean it.