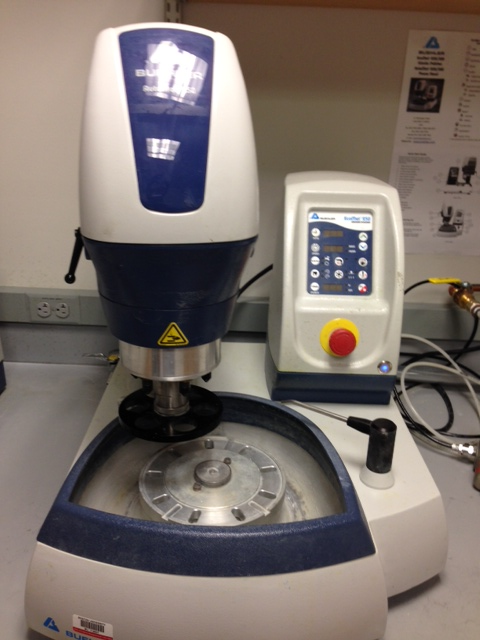

Polishing and Grinding SOP

Potential hazard in operation

- Splashing debris and water.

- Moving parts may hit fingers.

- Sharp objective.

- Electric shock.

- Compressed gas.

Check equipment and supplies

- Electricity supply should be ready. Turn the power switch ON (main switch is on the back).

- Water supply should be ready. Turn the water valve ON.

- When using auto polishing head, compressed air (35-40 psi) should be ready. Turn the compressed air switch ON

- Polishing head, rim and panel button must be clean. If not clean, clean with moist towel.

- Check polishing discs are clean and ready for use.

- Choose proper PPE for eye protection.

Preparations

- Make sure your polishing cloth or grinding paper are mounted properly. It should not be able to slip and all air bubbles must be removed.

- Make sure your specimen is suitable for polishing/grinding. The polishing surface must be flat and all edges (top and bottom) must be rounded (not sharp). Otherwise, there is a good chance that the cloth or paper will grab the specimen and pull it from your hand, or the edges may cut the cloth and possibly your hand.

- Make sure the rim is in place. Never operate the polisher/grinder without the rim in place.

Hand Polishing

- Start the motor and wait for it to come up to speed. Use less than 100 rpm for hand-hold polish.

- Gently lower the specimen to the center of the wheel. Once it is down apply pressure and slowly move it to approximately half way to the edge of the wheel.

- Slowly but firmly move the specimen in a clockwise direction.

- Use polishing media sparingly. Excess will just go down the drain or splatter all over the table.

Auto Polishing

- Mount the polishing disk on EcoMet as required.

- Mount sample holder and make sure the proper selection of pressure mode (single press and multiple press mode) on panel.

- Set timer.

- Using multiple press holder. Press and hold both green buttons till the holder touches the disc. Then release buttons.

- Mount 1.25" dia. specimens into the mount holes. Put the alignment chuck in.

- Press both green buttons once.

- Use polishing media sparingly. Excess will just go down the drain or splatter all over the table.

- Apply less than 15N on polishing cloth and less than 70 rpm. High load may delaminate the cloth and damage specimens. High speed may spin away the polishing paste.

- Never polish with the sand paper with metal ring frame. Use sand paper with back adhesive.

Polishing/Grinding Sequence

- Grind from 70 μm - 45 μm silicon carbide disc or 120-230 M sand paper to a reasonable flat surface or expose interested layer.

- Polish with 15 μm silicon carbide disc or 600M sand paper to remove large scratches.

- Polish with polishing medium 6 μm, 1 μm, 0.3 μm, and 0.05 μm diamond or alumina suspension.

- Specimens must be ultrasonically cleaned between two grits of polishing/grinding.

- Diamond suspension is very expensive, $750 per gallon. Use sparingly.

- Use alumina paste from PSI for soft materials. Nylon finishing cloth (PSI-621-8 or Buehler Microcloth) is best for alumina paste.

Finishing Up

When you are completely finished using the polisher/grinder you must do the following:

- Turn off the power, air and water of polisher/grinder.

- Clean up the disk (platten), making sure you remove the polishing cloth and polishing residue.

- Reusable cloth must be rinsed thoroughly, wipe dry, and leave in the designated place with clear mark.

- Clean the bowl, giving it a final rinse with water.

- Wipe the head holder, buttons, and rim with a moist towel or sponge. Dry them if necessary.

- Wipe up the area around the polisher/grinder. Dry it if necessary.

Polishing Supplies

- Silicon carbide sand paper 120, 180, 400, 600, 800, 1200, 2000 (Buehler Ltd, Lake Bluff, IL, USA)

- Diamond grinding disk, Apex Coarse Grinding Disc, Metal Back, 125 um (Buehler Ltd, Lake Bluff, IL, USA)

- Diamond grinding disk, Apex Disc, Metal Back, 45 um, 70 um (Buehler Ltd, Lake Bluff, IL, USA)

- Diamond grinding disk, Apex Disc, PSA 125 um (Buehler Ltd, Lake Bluff, IL, USA)

- Diamond grinding disk, UltraPrep Disc, PSA 70 um, 45 um, 15 um (Buehler Ltd, Lake Bluff, IL, USA)

- 6 um (yellow coded), 1 um (blue coded) diamond suspension (Buehler Ltd, Lake Bluff, IL, USA)

- l um, 0.3 um. 0.05um alumina suspension paste (Precision Surfaces International, Inc., Houston , TX)

Tips

- Note: Surface should be shinning after 6um polish, and will be mirror-like after 1-0.3um polishing.

- Note: Do not use continuous water on diamond/alumina suspension.

- Note: Magnetic disk should be dried to hold magnetic polishing disk strongly.

- Note: ©2015-2021

Related Documents

ABRASIVE GRADE COMPARISON CHARTGuidance for polishing cloth Struer Polishing Methods, Metalogram