|

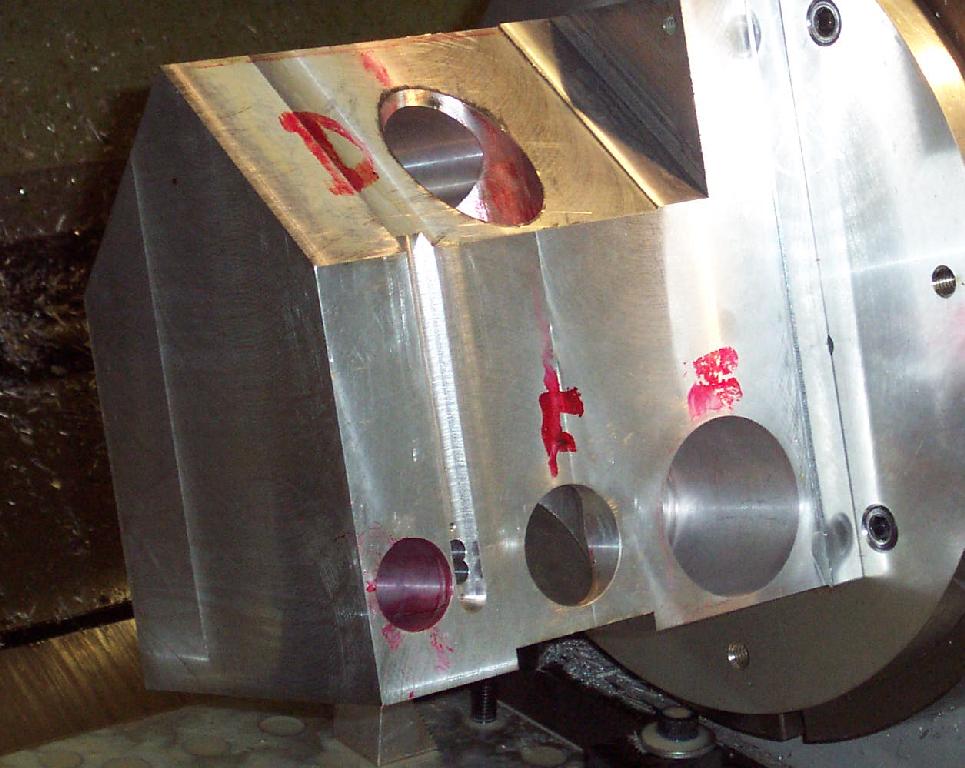

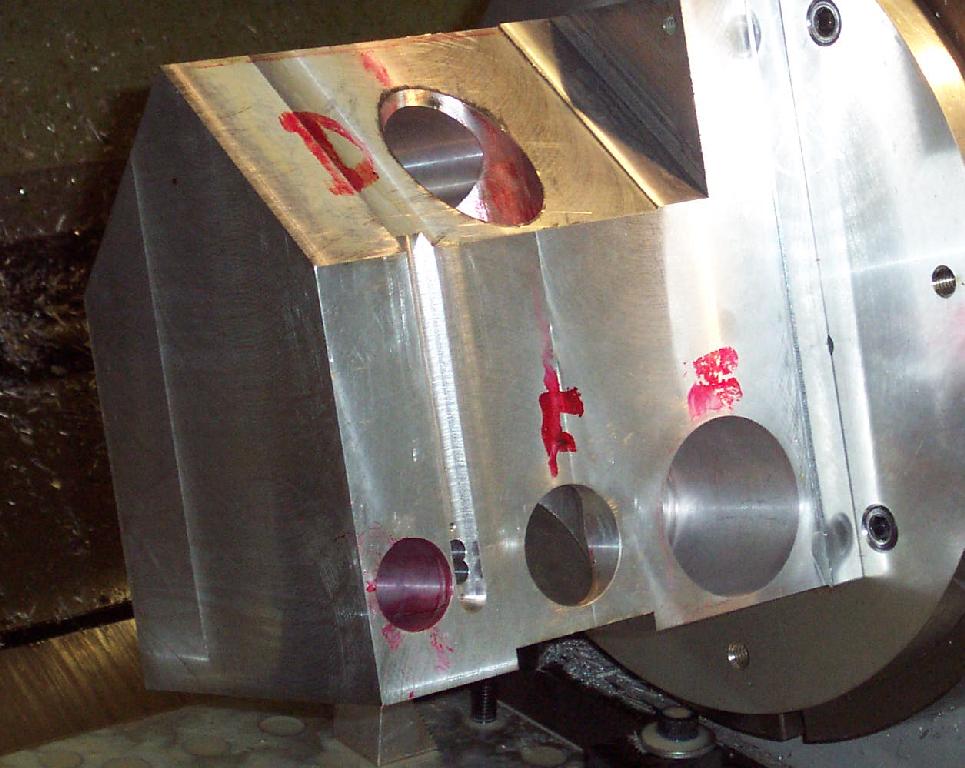

Camera clock with finished bores |

|

Camera block with finished bores (second pic) |

|

Camera block with finished bores, oblique |

|

Camera block with finished bores, underside view |

|

Camera carriage showing reed switches |

|

Cold optical bench, rotated 90 deg |

|

Collimator aft section, after rough machining |

|

Collimator fore section, after rough machining |

|

Collimator mid section, after rough machining |

|

(Left) Cryostat front vacuum cover and window holder. (Right) Internal cold shield (connects to cold bulkhead) |

|

Cryostat shell, with bulkhead replacement cover, wrapped for heating, on cryostat cart |

|

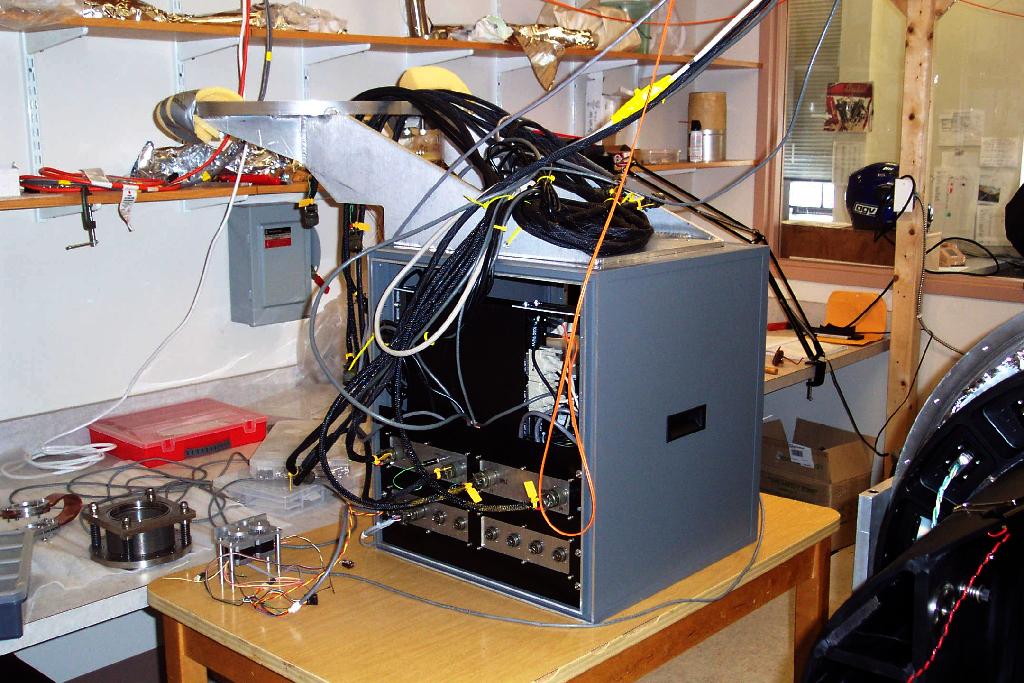

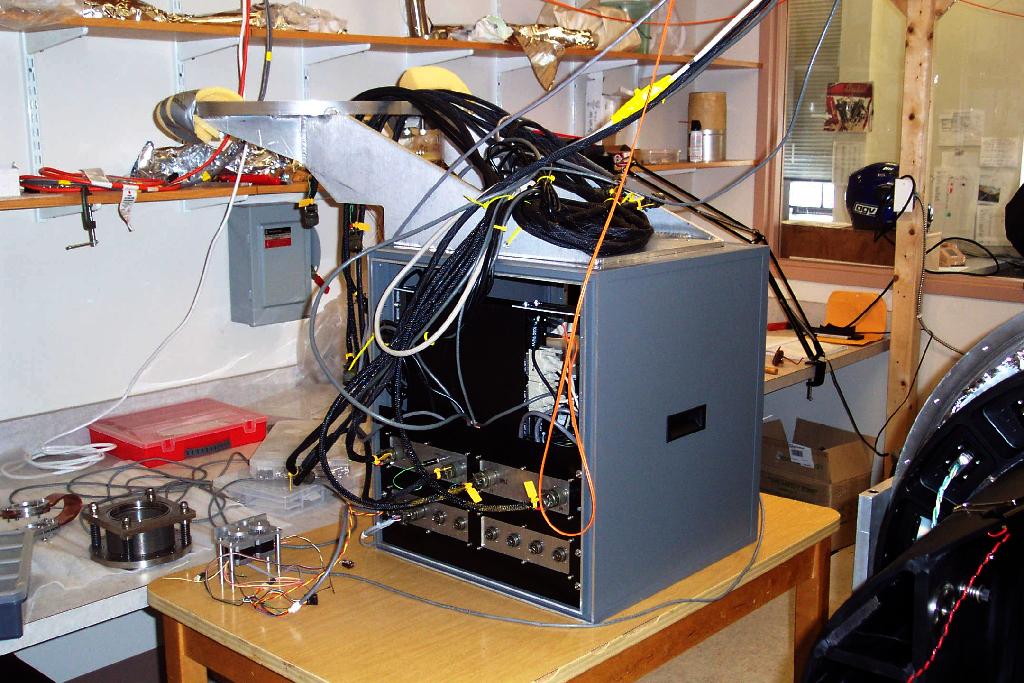

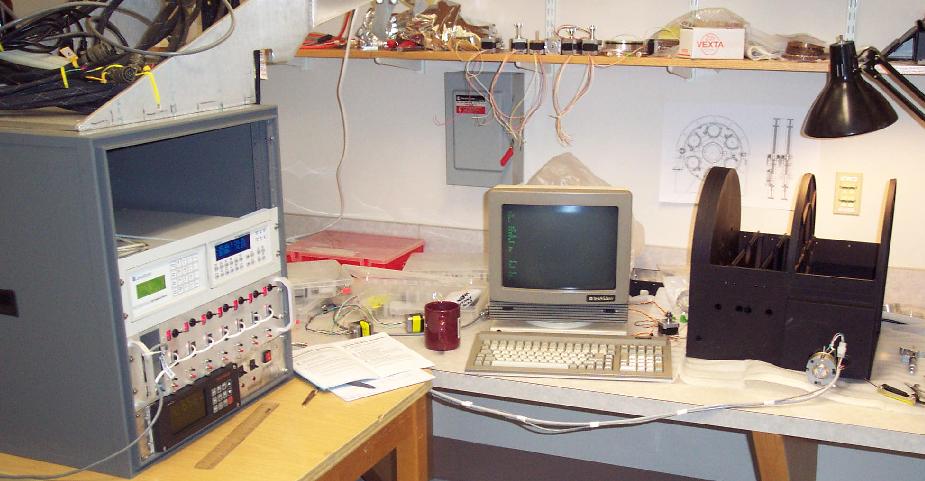

Electronics rack, backside view, with stepper motor test unit at left, and open Mimir cryostat at right |

|

Electronics rack, front view. Showing thermal monitoring, control units at top, motor controller boards in middle, and vacuum monitoring unit at bottom |

|

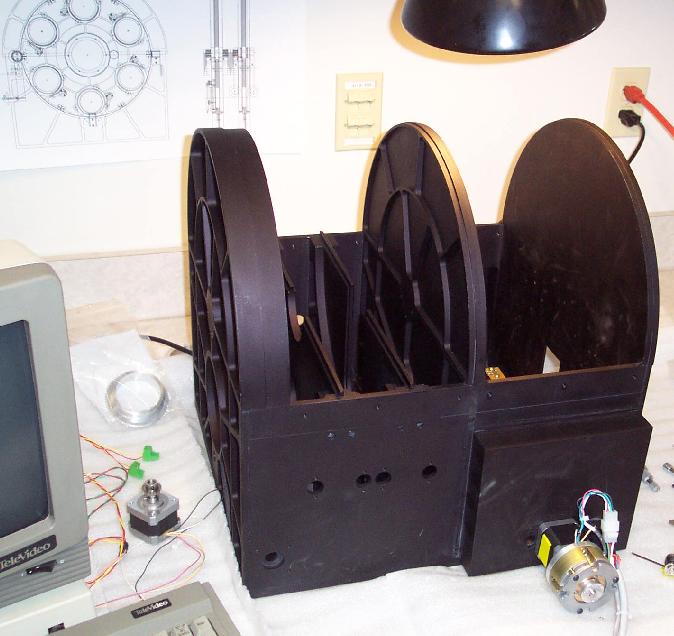

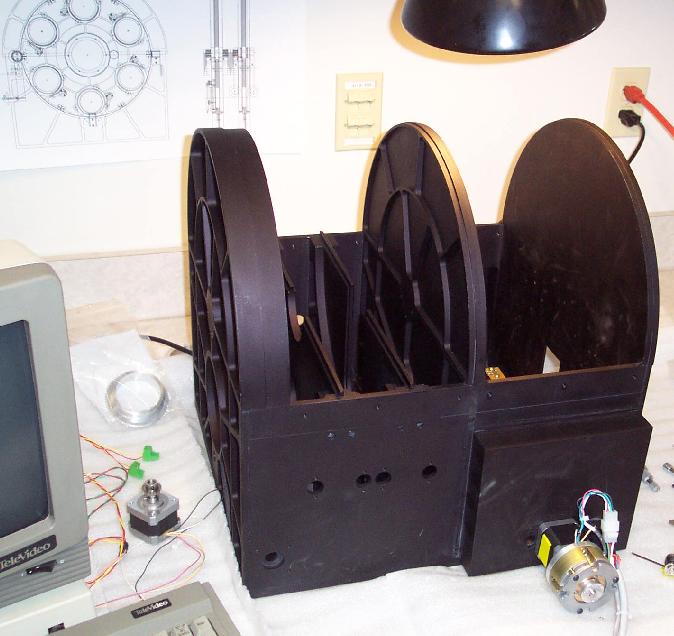

Filter box during camera carriage testing, with motor & brake at lower right. |

|

Cold Head 1st stage vibration isolator unit (bellows at front) and thermal strap unit (copper straps at left). |

|

Four anodized filter wheels, prior to assembly |

|

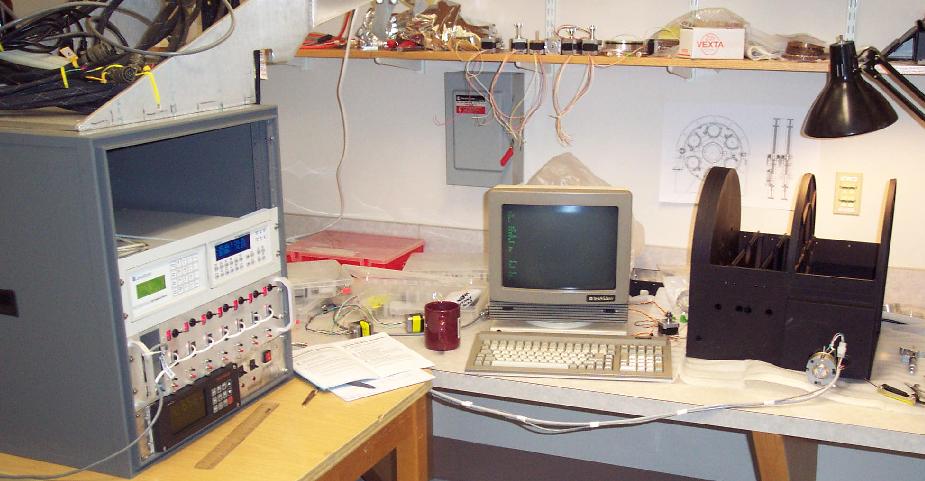

Test bench set up of Mimir electronics, communication terminal, and filter box, with direct cable connection to motor & brake. |

|

Optics cabinet with vacuum jars holding optics, grisms, filters. |

|

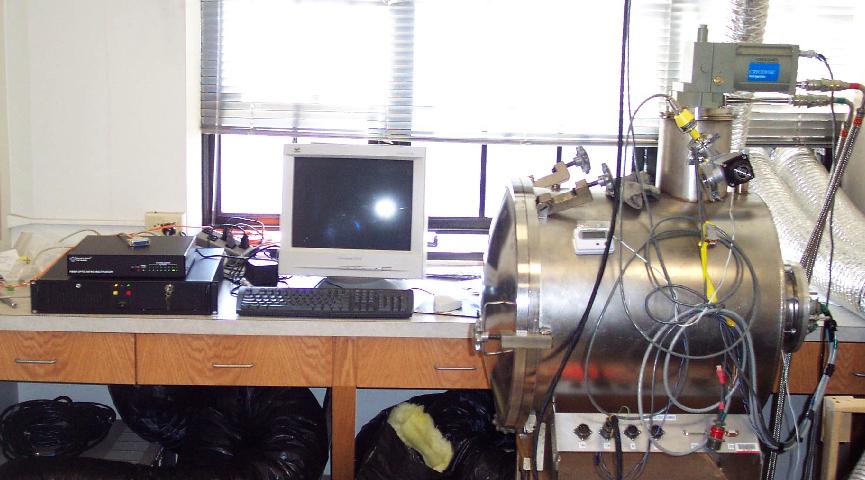

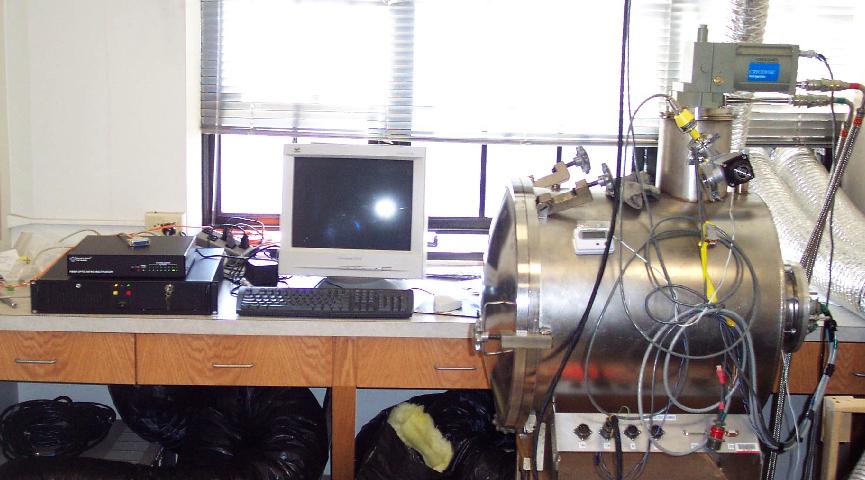

Cryovac test chamber with cold head mounted at top, compressor at bottom right |

|

Side view of cryovac test chamber during cooling test. |