|

Front of Filter Box. Two filter wheel drive stepper motors are installed below the hub mount, two are on the table awaiting installation. The large round opening below the mounted motors is the receptacle that will hold the collimator. The long screws surrounding the opening hold the collimator to the filter box. |

|

Drive gears on the two motors, seen from within the Filter Box. |

|

First batch of lenses shipped from Lambda Research Optics. ZnSe and ZnS optics. |

|

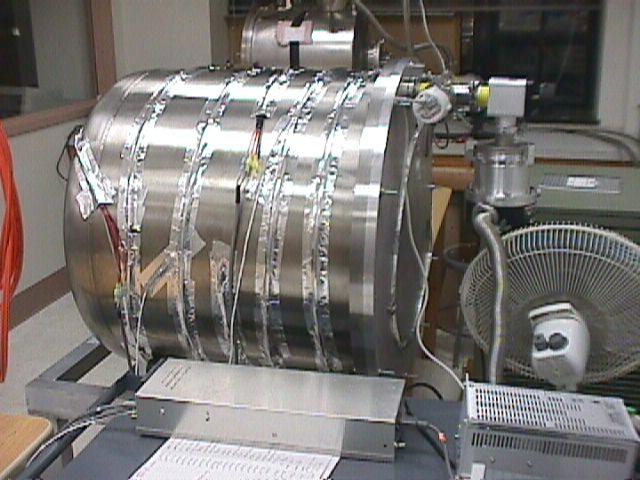

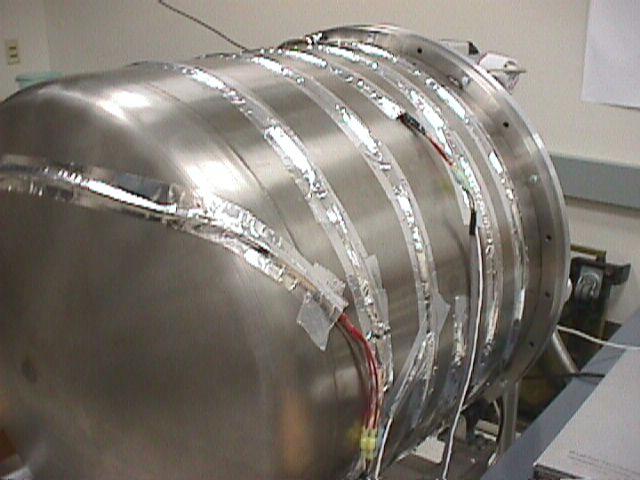

Cryostat cover with heater tape wrapped around it. The purpose of the heater tape was to try to warm the shell and the enclosed MLI in order to boost outgassing and deepen the vacuum achieved. |

|

More heater tape wrapping details. In addition to the tape, temperature sensors (thermocouples) were attached to the shell in two places. |

|

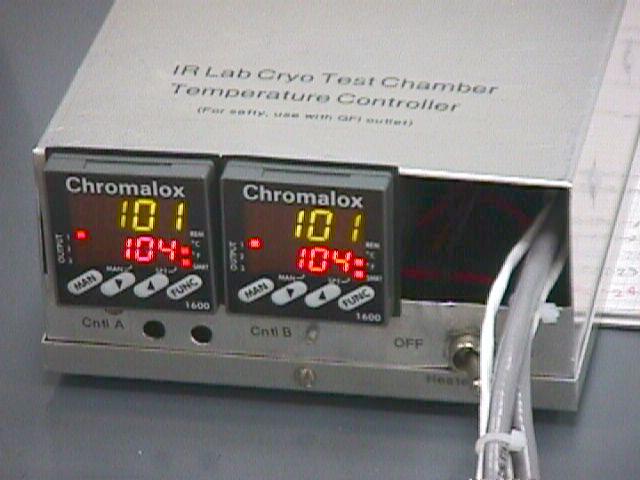

Closed-loop temperature controllers for the shell heaters. Two independent circuits were used, each supplying up to about 300 W of heat. Here the setpoints are at 104F and the thermocouple sensors report 101 F. |

|

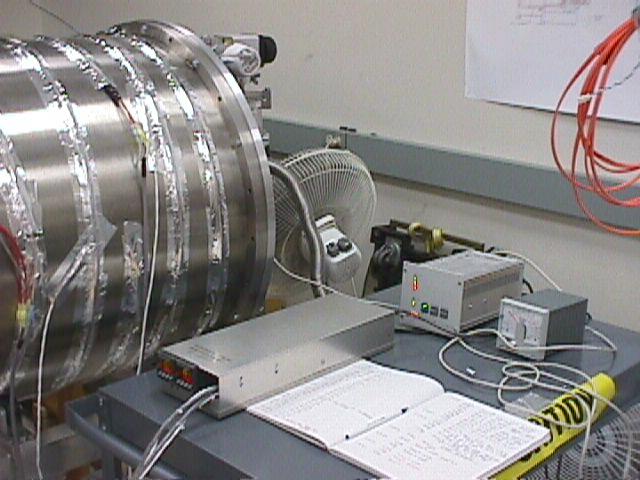

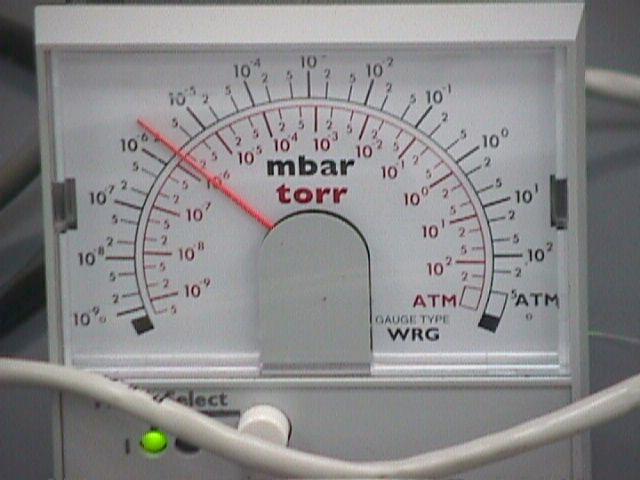

Shell pumping and heating set up. Heater control in foreground, turbo vacuum pump controller behind it, multirange vac gauge readout at right. |

|

Vacuum reading after two weeks of heating and vacuum pumping. Value shown is about 2x10^-6 torr. In the end, we abandoned the shell heater system for routine Mimir work. We found that the MLI refills with water and other contaminants promptly upon reopening, that the adhesive backing of the aluminum tape used to hold the heater tape against the cryostat shell went soft with heating and left a sticky mess on the shell. Alex spent a couple of long days cleaning the outside of the cryostat shell and we retired the shell heating system for good. |