|

Stepper Motor |

|

Stepper Motor with Cover Removed. Bearing race to be degreased is

still on motor shaft. The key to degreasing and not ruining the motor

is to leave the rotor in place while the bearings are degreased. previous

groups have pulled their motor rotors, ruining the permanent magnet

fields. |

|

Bearings exposed on two motors. |

|

Degreasing multiple stepper motors. Filter wheel hub components

and gears are behind the motors. Motor cryovac test jig is at right. |

|

Innermost shaft of the filter wheel hub assembly, with one drive

gear installed, resting in the brazed, bead blasted, but unanodized

filter box. |

|

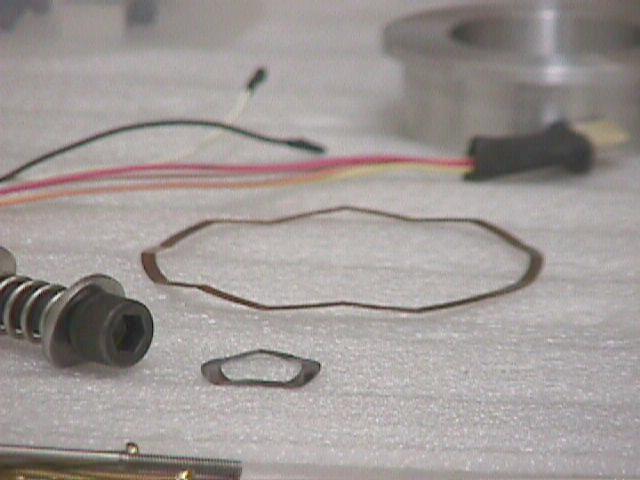

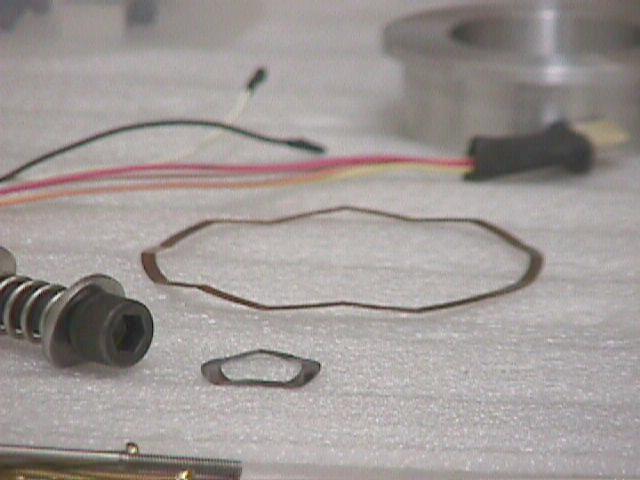

A couple of home-made wave washers. Machined from steel sheet stock,

then bent to create the wave form, these washers are used to both

locate parts radially and to provide spring force axially. |

|

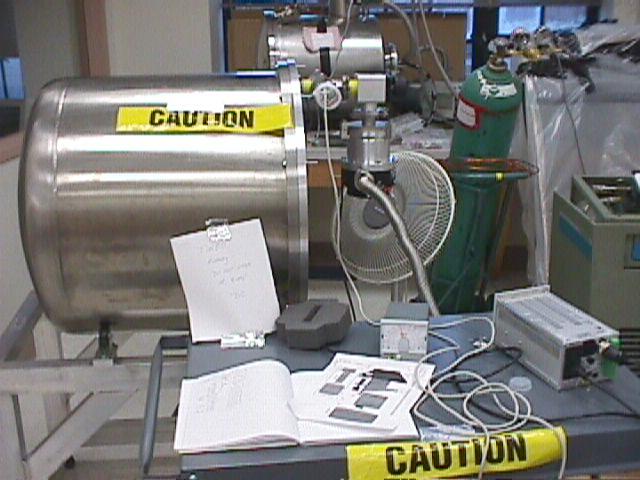

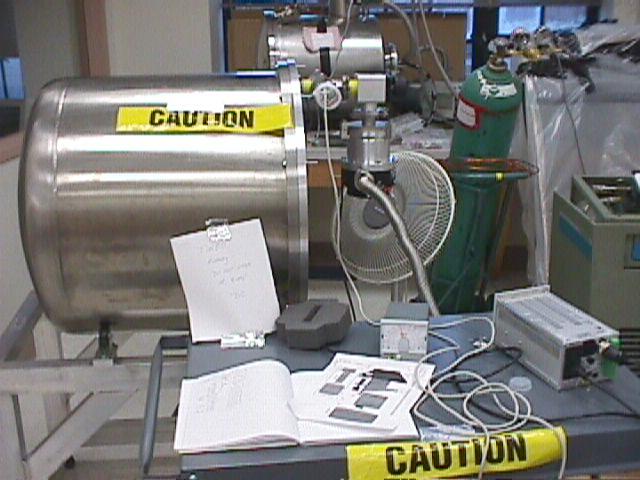

Stainless steel cryostat cover, with flat front cover and vacuum

pumping system attached, about to begin pumping to keep the MLI inside

clean and dry. |

|

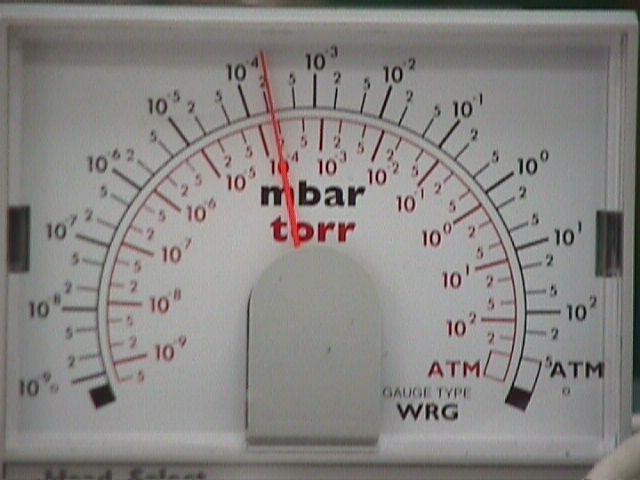

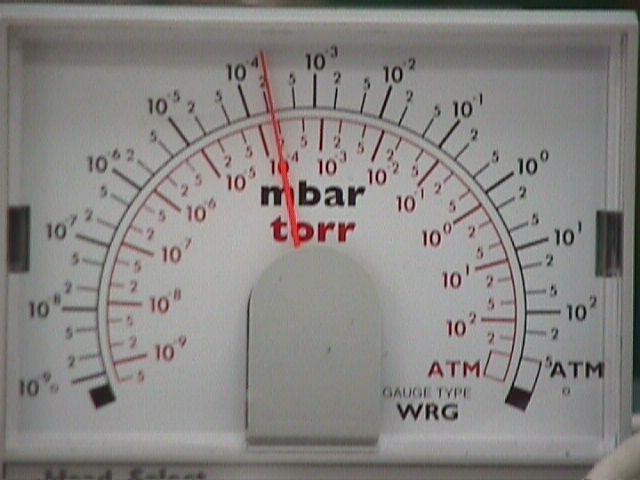

Vacuum gauge reading on the cryostat shell with the MLI. Value shown

is about 2x10^-4 torr. |

|

Blackbox fiber transceiver (fiber to 8 RS232 channels) resting on

the I/O subrack chassis. |