|

Cold bench, with LN2 ring installed, after bead blasting and anodizing. |

|

Detail, showing the LN2 ring and transition pieces. |

|

Finer detail, with transition pieces. Note LN2 ring is welded into

slot in cold bulkhead. |

|

Filter box, on returning from dip brazing (with one already anodized

cover). |

|

Front view of brazed filter box (filter bay cover intentionally

askew), after bead blasting. |

|

Inside view of filter bay of filter box, after brazing and bead

blasting. |

|

Internal view of filter box after brazing and bead blasting. Note

that post-brazing, the filter box is a single integral element with

not moving or removeable parts. |

|

Front oblique view of brazed, bead blasted filter box. |

|

Side view of brazed, bead blasted filter box (and anodized camera

bay cover). Dimples on filter bay cover are brazed screw heads used

to secure filter bay cover to filter bay bulkhead tops. |

|

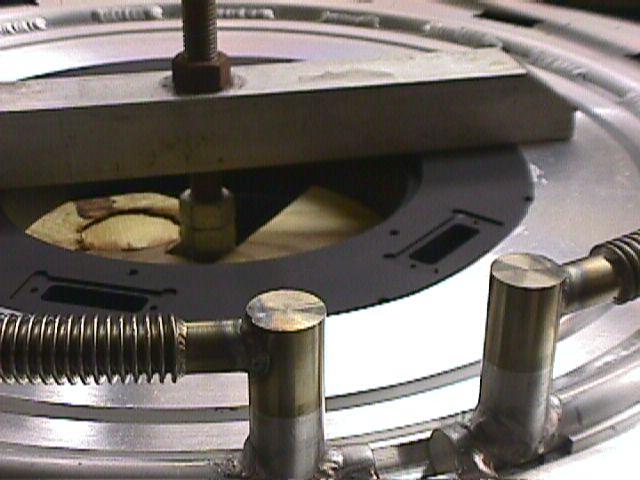

POL wheel and unpopulated POL filter cell, held in place by shoulder

bearings and lever arm attached to flex-pivot. This system registers

the location of the HWP cell, while providing rotational freedom.

A gear is added to the cell to engage the drive gear of the HWP drive

system when in the optical beam. |

|

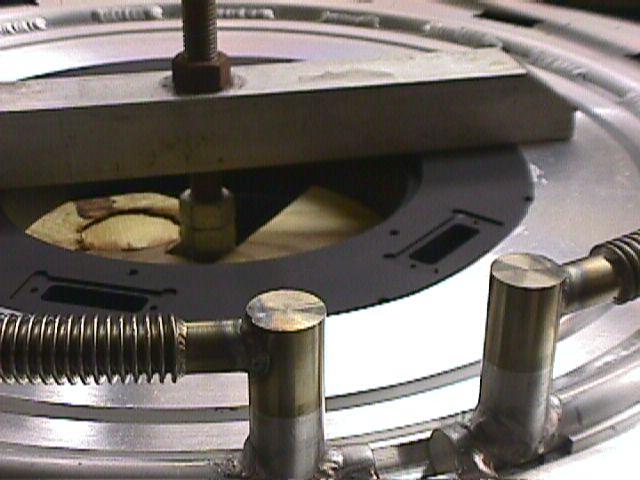

POL cell being removed from POL wheel. The lever arm on the flex-pivot

moves enough to allow the cell to be easily removed, but holds the

cell tight when in place. |

|

Overview of POL wheel, showing the six cell locations and hardware

for one cell holder. |