|

LN2 storage dewar, during Mimir pre-cool. |

|

LN2 pre-cool system. LN2 flows into Mimir's internal cold bulkhead LN2 loop via a short hose from the storage dewar. After exiting Mimir, the cold N2 gas is flowed through copper tubing (on top of clean room) until warmed to room temperature, then put through a flow meter to ascertain the LN2 flow rate. |

|

More details of the LN2 pre-cool configuration. The input and exit hoses are highly insulated to reduce heat ingress and parasitic LN2 boiling prior to entrance into Mimir. |

|

Back side view of Mimir electronics rack |

|

Another back side view |

|

Vacuum pumping set up. Note oil-based mechanical pump backing up turbo pump. |

|

Details of the NW40 valve on the warm bulkhead of Mimir, the turbo pump, the NW25 electronic valve, and flex hose to the mech pump. |

|

BA high vacuum gauge, as initially configured on Mimir. |

|

CCR cold head location between mounting flange and warm Mimir bulkhead. |

|

Mil-Spec connectors carrying detector signals and lines from ARC controller to Mimir warm bulkhead connectors. |

|

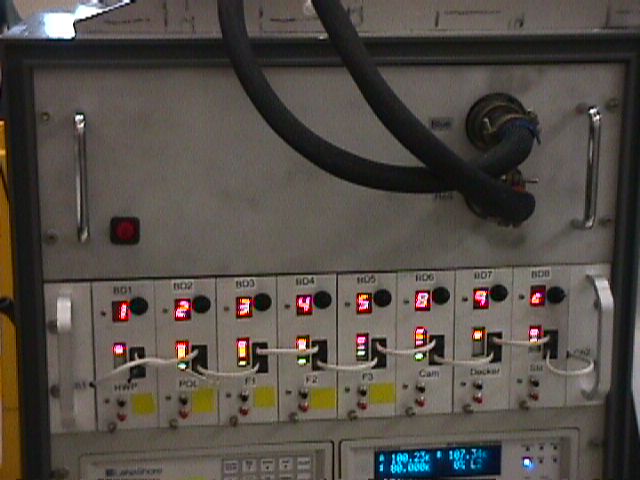

Electronics rack, front view |

|

I/O boards, zoomed pic |

|

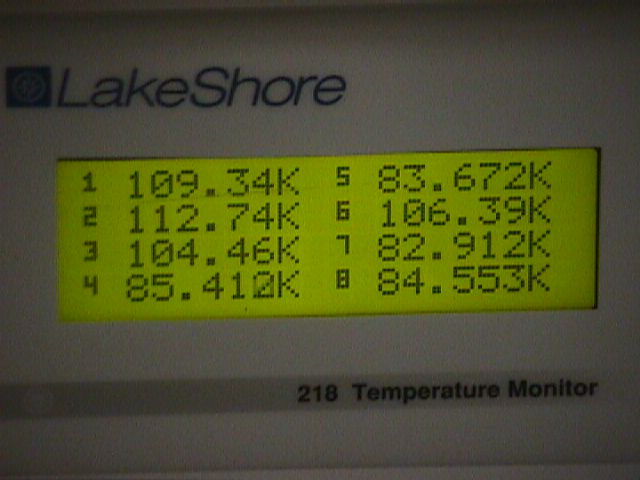

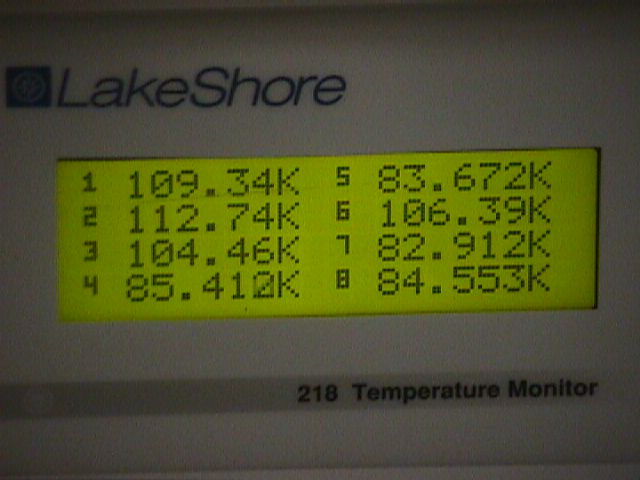

LakeShore 218 unit readouts |

|

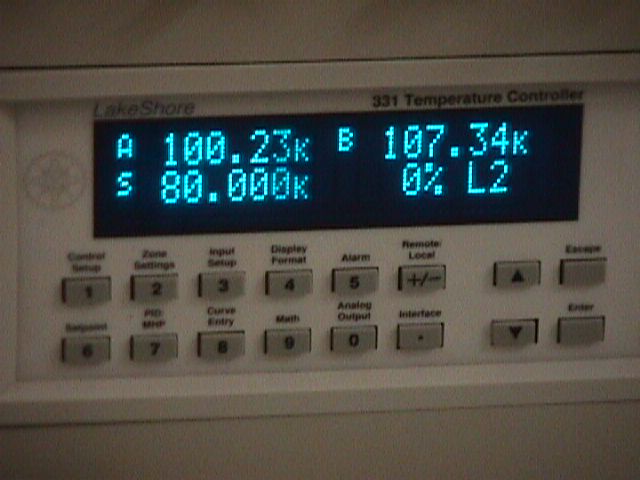

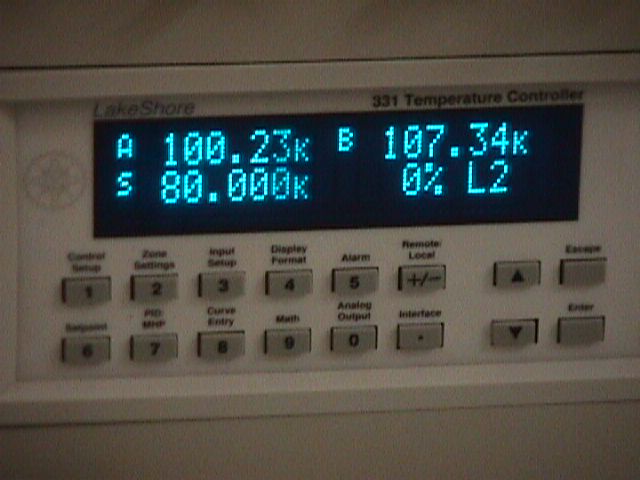

LakeShore 331 temperature controller readout |

|

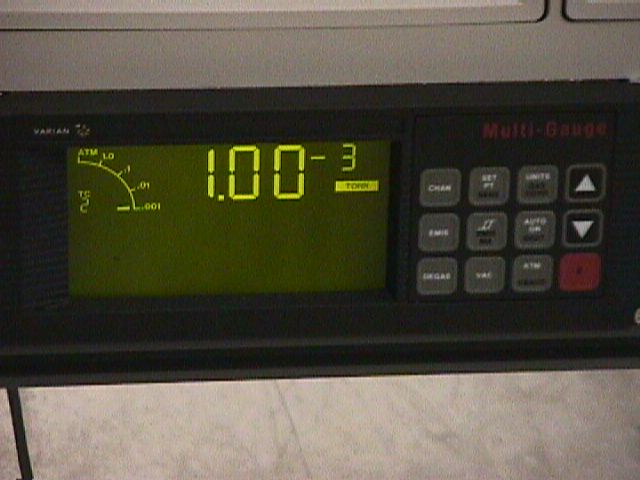

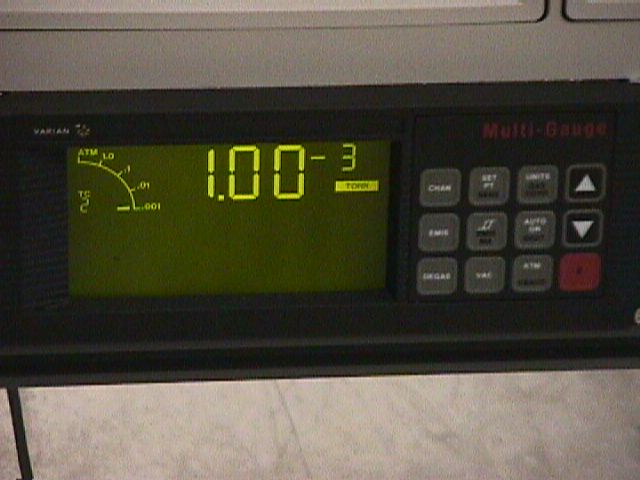

Varian vacuum gauge controller readout |

|

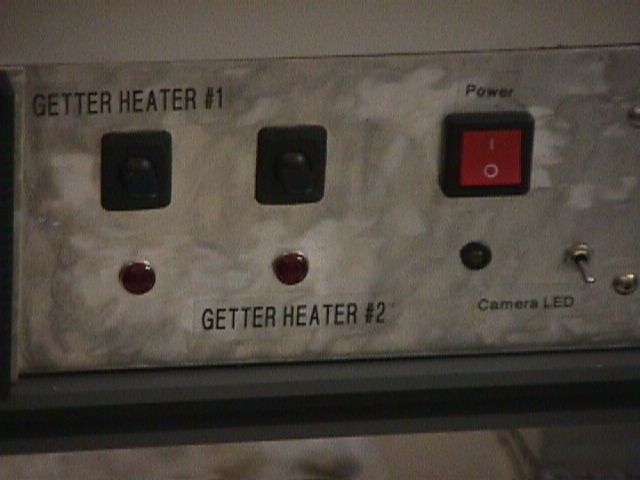

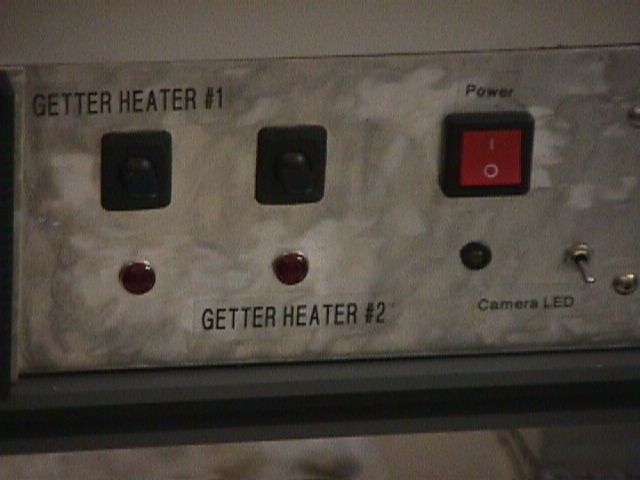

I/O subrack power and getter heater power control |

|

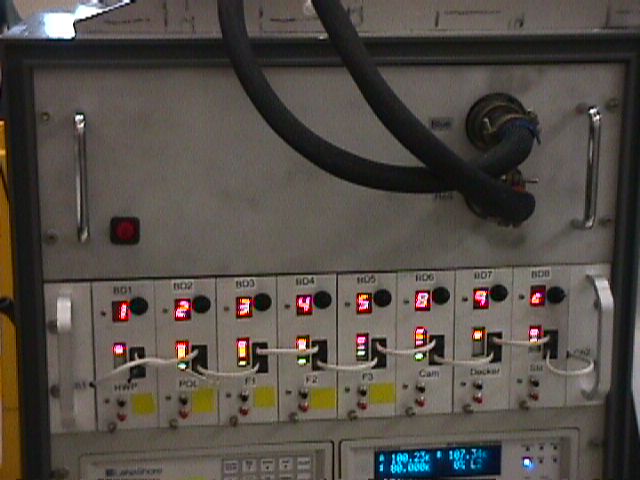

Electronic rack I/O subrack |

|

Mimir side view, showing vacuum needle fill valve |

|

LN2 fill hose to Mimir pre-cool loop |

|

Detector signals connector headers and Mil-Spec connectors on warm bulkhead. |

|

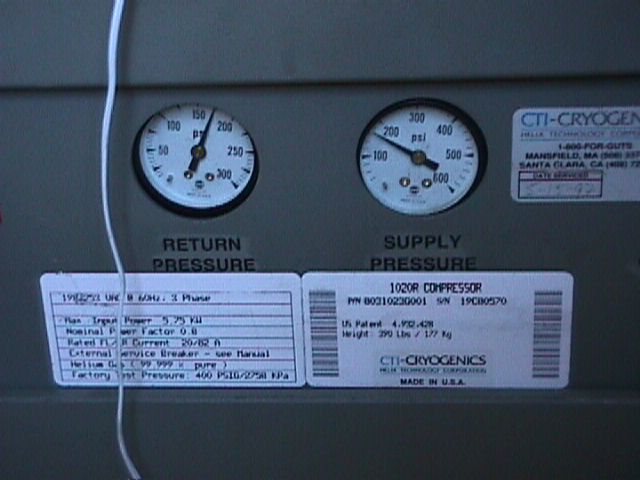

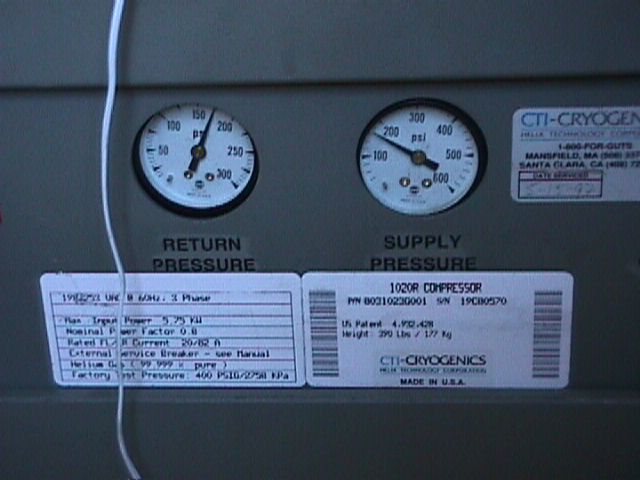

Helium compressor (CTI 1020R - aircooled) |

C |

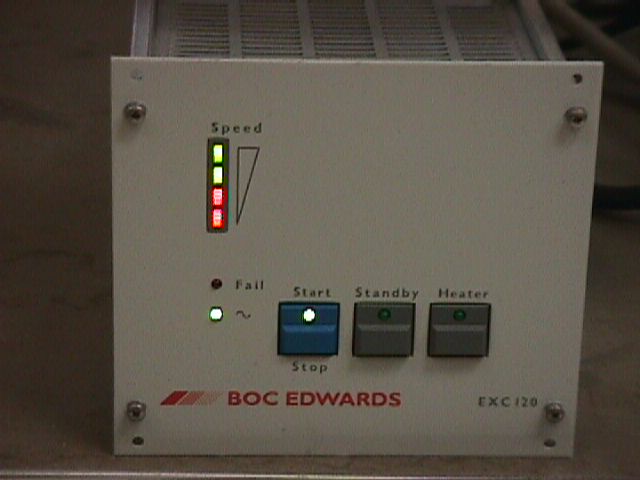

Compressor front panel switches |

|

Compressor back panel supply, return pressure gauges |

|

Compressor Fill/Vent valve and fitting. |

|

Helium supply and return flex line fittings |

|

yggdrasil computer and black-box fiber to 8X-serial converter |

|

Mimir array controller computer (Sun sparc station) |

|

Gas flow meter, showing 145 SCFM during LN2 pre-cool |

|

zoom of same |

|

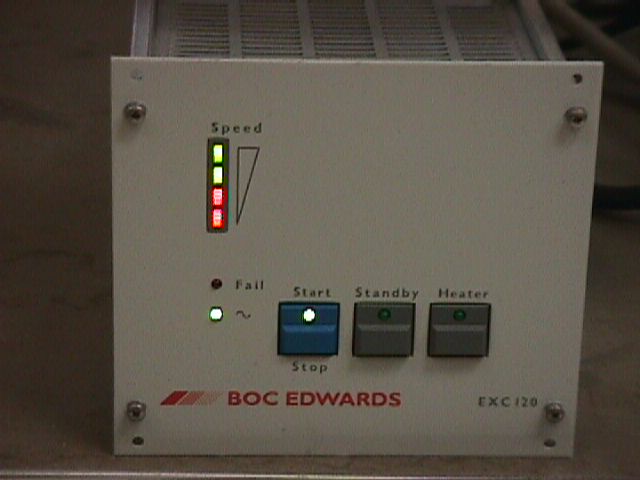

Turbo pump controller |