|

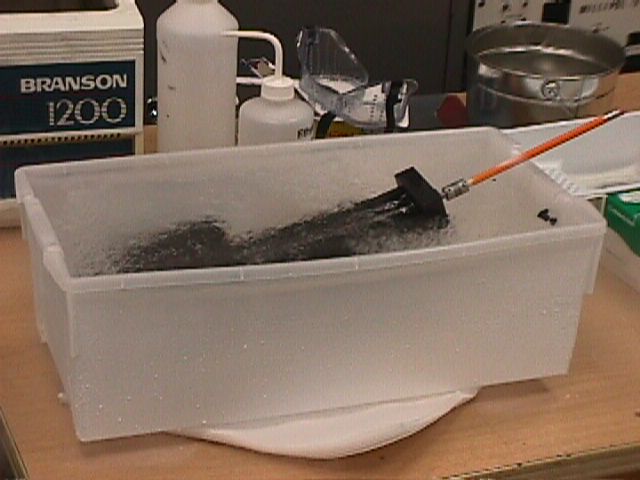

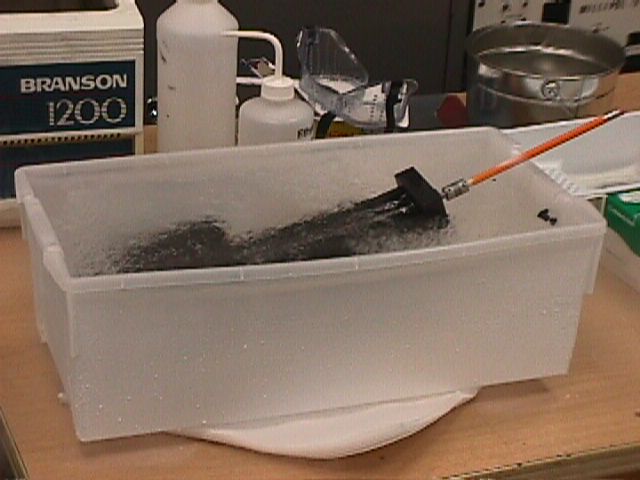

Camera (THK) rail in LN2. Pencil attached to drive shaft enabled feeling when the rail bearings were seizing. |

|

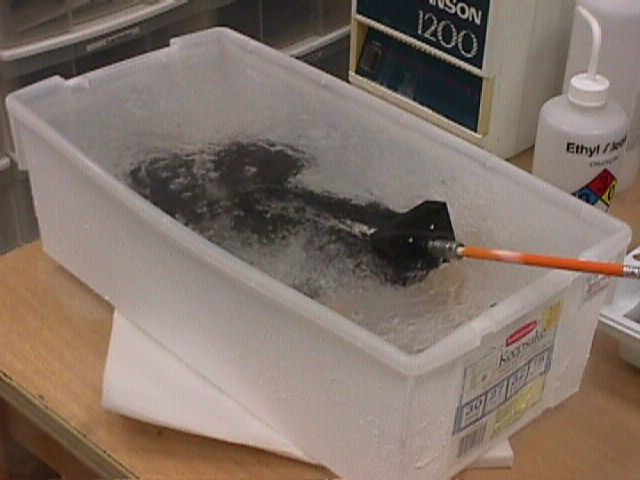

Same view, oblique. Camera rail in bath of LN2. |

|

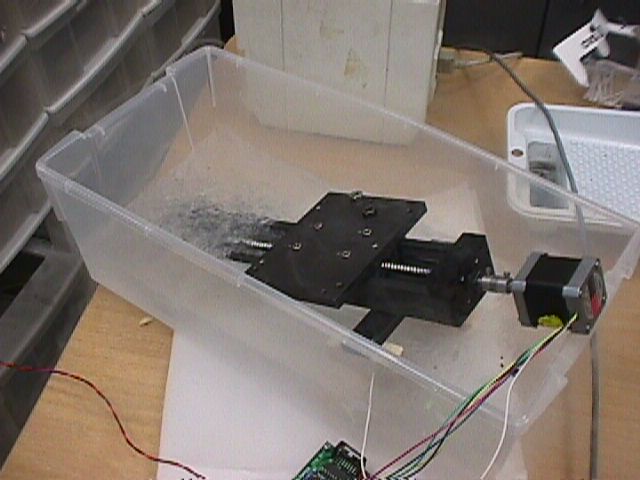

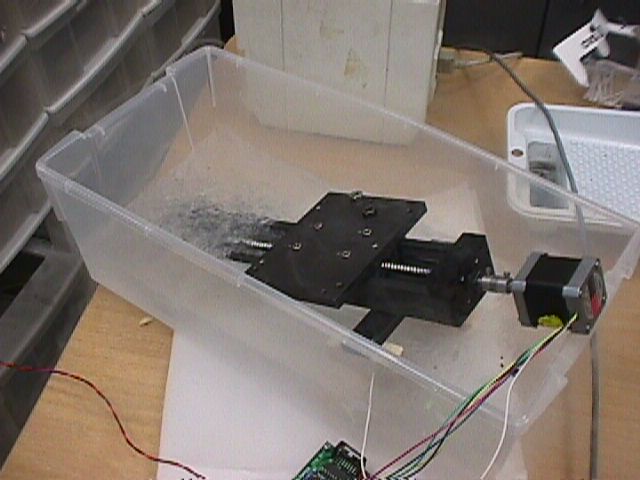

Set-up with stepper motor drive, prior to second LN2 test. |

|

Detail of stepper motor, flex coupling, and front bearing race for THK rail. The stiction problem was traced to a plastic piece pushing the rail bearings into their race. The work around for Mimir is to continuously run the rail back and forth while cooling down, so as to not "dimple" the plastic piece, but to furrow it smoothly. |

|

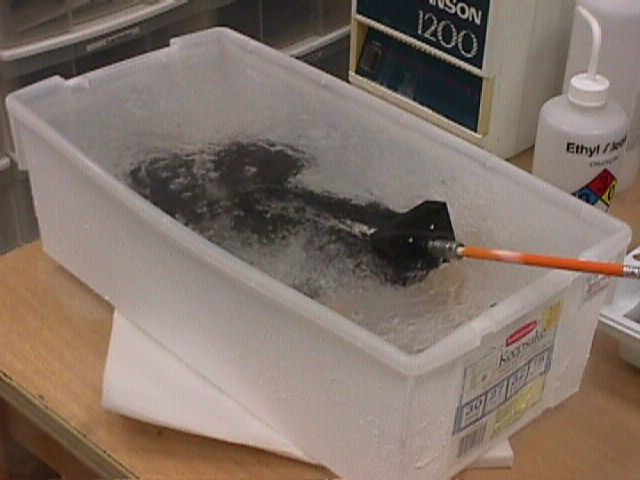

Initial LN2 cooling for second test. Done slowly to see when motor fails to overcome stiction. |

|

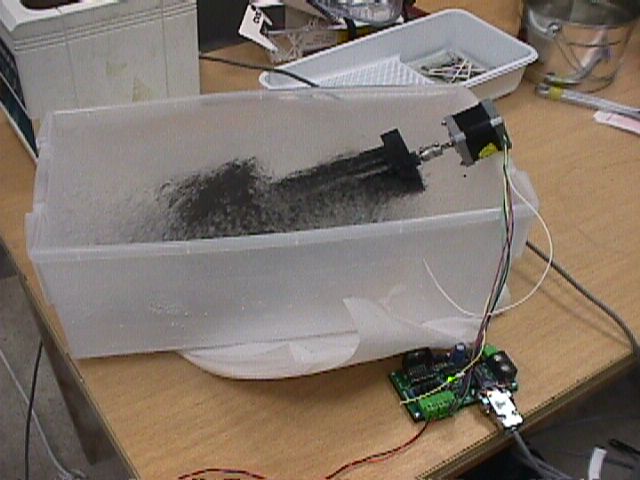

More LN2 added to half-cover the rail. Conduction does the rest... |

|

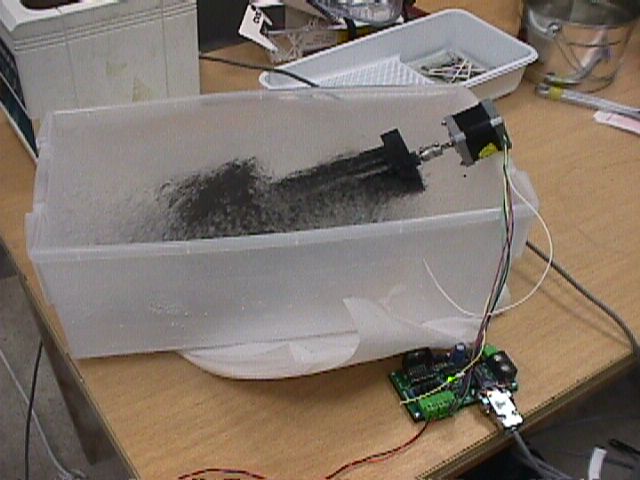

Filled LN2 to contact the front bearing race. By continuously operating the motor to keep turning the rail screw, we found we could avoid stiction all the way to fully cold. This was a nice lab success that directly informed operations of Mimir. |