2003/04/14 preparation for April 2003 cold test run this test was to run the 2nd stage cooling system (cold pipe), verify detector unit could get to 35K and stay there, re-re-test the camera unit, and test the decker system. we also elected to try the gas-assisted cooldown, with dry N2 gas at 0.1 atm. To isolate the effects of this gas assistance from the strong copper thermal strapping of the previous run, we replaced the heavy duty copper straps with the minimal ones (8 gauge wire composed of about 100 strands of 36 gauge OHFC). The cold head was disassembled and the SS shell retrued in a lathe to make up for the bending introduced when the aft cold shield hit the end of the cold pipe during assembly for the March cold run. Because of the new sounds in the CCR head at the beginning of that run, we did not run the cold head during that run, and only ran LN2. For this April run, LN2 cooling was assisted by the CCR until the 1st and 2nd stages approached 80K, at which time the CCR was turned off. When the LN2 was used up (about 24 hours later), the N2 gas was pumped out and the CCR restared. The CCR ran for 6 days until we turned it off. The second stage worked very well, but the first stage bottomed out at 30 W instead of the 50-75W it is rated for. We believe a first stage seal is bad and will replace it before the next cold run. |

|

|

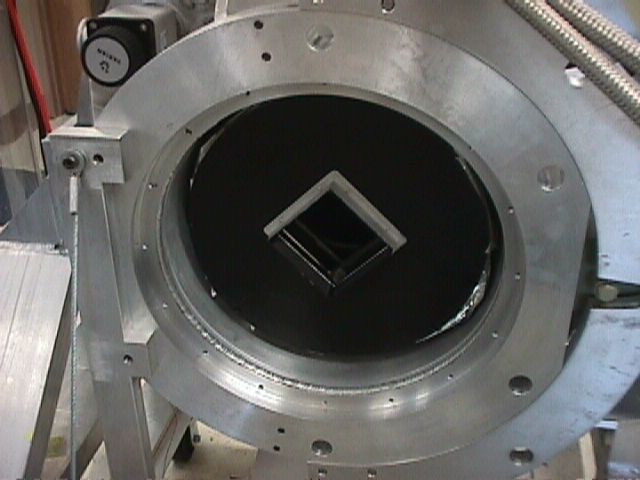

Foreward Cold shield cover with box baffle |

|

Details of box baffle surrounding the front cold shield cover |

|

Filter box minimal thermal strapping for this cold test |

|

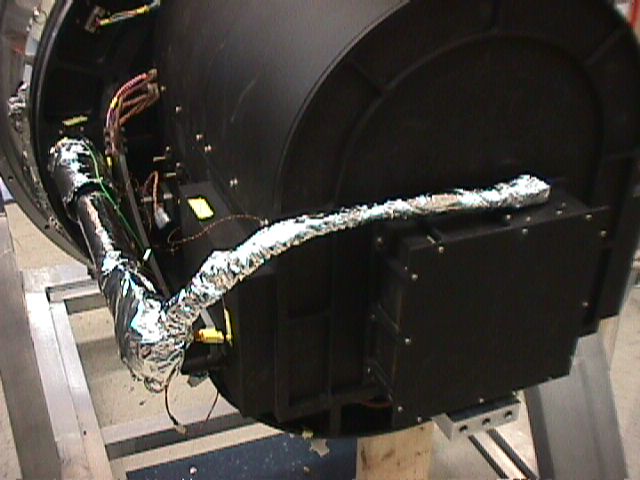

2nd stage configuration and MLI wrapping |

|

Filter box with thermal strapping |

|

Clemens Clamp with minimal thermal straps to filter box |

|

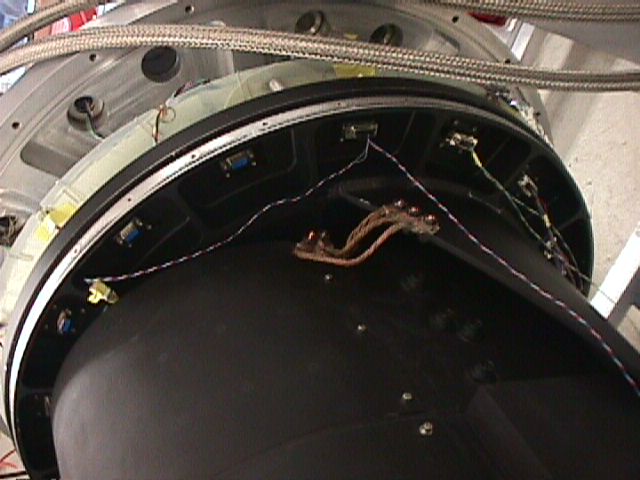

1st stage CCR configuration |

|

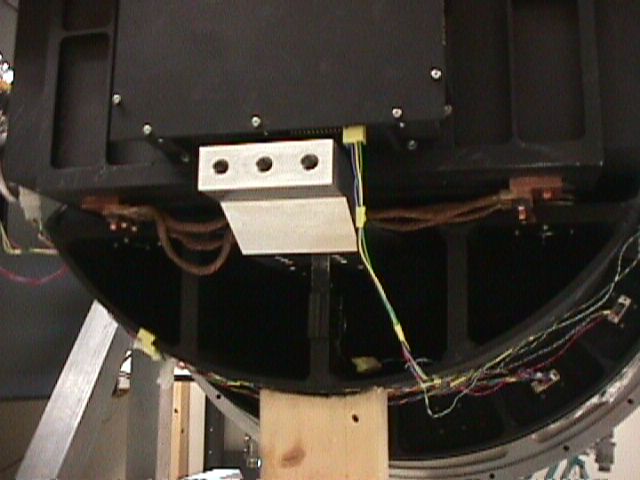

Baffles and ball keepers (anodized rings with 3 holes in each to trap ball bearings) |

|

Test lens (big aluminum piece mimicking the LiF lens in the central portion of the collimator), with temperature sensor attached. |

|

Back-facing portion of the front box baffle. This piece goes between the front cold shield cover and the slit/decker system, and actually decends into the pocket of the decker car to ensure a close fit and no light scattering. |