|

Front view of warm bulkhead. Collimator cold shield has been installed and wrapped with MLI (aluminum covered mylar -- seen at center). Copper tubing connects to inlet and outlet of LN2 precool loop. This cooldown used only LN2. Note that the CTI cold head location (at right, just inside supporting plate) is filled with a vacuum-sealed plug. |

|

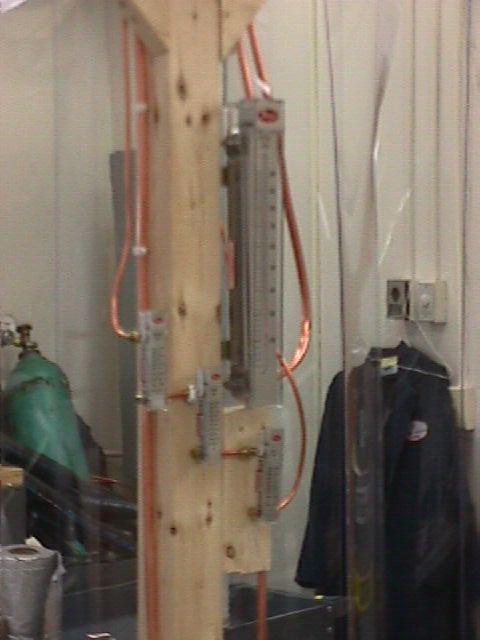

Controlling the cooling rate was a goal of this cooldown. This was done by capturing the N2 gas leaving the precool ring outlet, warming it back to room temperature, and running it through a series of flow gauges (the tall rectangular pieces mounted to the wooden post). The initially installed flow gauge stack spanned some three or four powers of ten in flow rate. We quickly found that only the highest rate gauge (the largest one) was needed. |

|

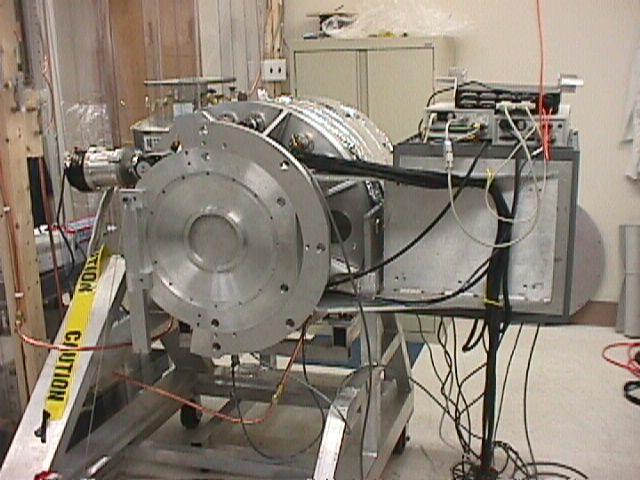

Final setup for first cold test. The front cover has been installed, along with the aluminum blank replacement for the front lens. Fiber I/O and temperature monitors and control units are resting on the face of the electronics rack, not yet installed within the rack. The turbo vacuum pump is attached to the NW40 valve (at left) leading to the cryostat volume. |

|

LN2 precool loop outlet fitting, showing location of its temperature sensing silicon diode (held under the kapton tape [orange]). |

|

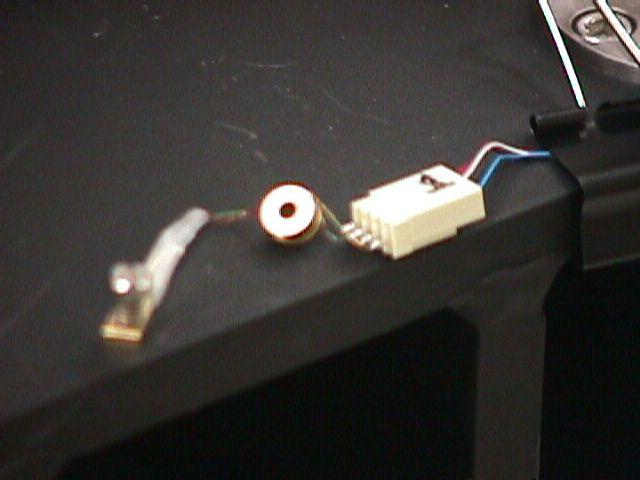

Silicon diode temperature sensor (and brass bobbin) attached to the cold optical bench. |

|

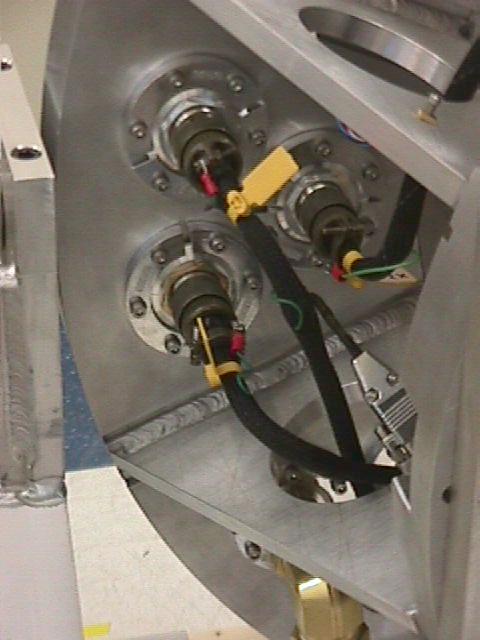

Temperature monitor and control cables attach to the front of the warm bulkhead using individually-keyed MIL-spec locking connectors. |

|

Inside Mimir, sensor wires connect the warm bulkhead MIL-spec connectors to DB15HD plugs that plug into DB15HD gender changers mounted in the face of the cold bulkhead. Connected this way, little heat is conducted into the cold volume via sensor and motor leads and a light-tight environment is maintained in the cold space. The corregated stainless steel bellows connecting the LN2 precool inlet and outlet to the loop embedded in the face of the cold bulkhead. Also seen is the green G10 collar that connects the cold and warm bulkheads. |

|

Final configuration of the shell heater system. Wrapped in aluminum foil to reduce radiative heat losses and allow higher shell temperatures. |