|

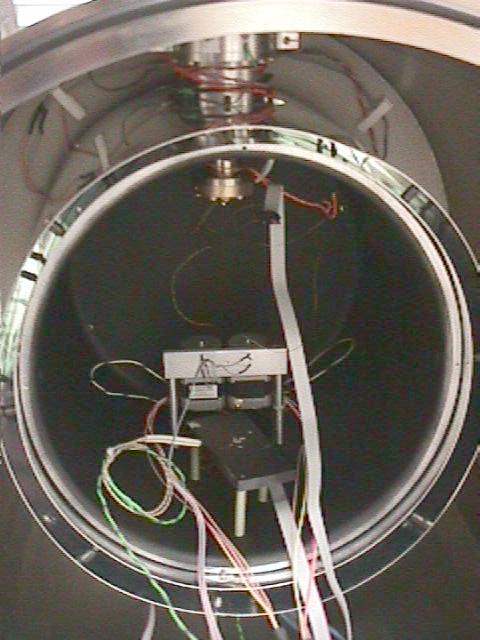

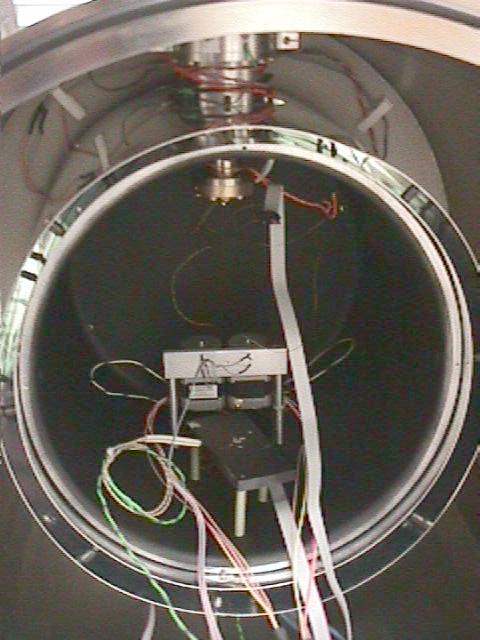

Cryovac test chamber on the bench in the lab. The chamber began

its life (before it knew us) as a pressure cooker, including having

6 "dogs" with screws to hold the cover on under pressure.

We modified it by adding the "stovepipe" at the back that

supported the CTI 1050 cold head. Inside the test chamber, the first

cold station (50 K) was bolted to a modified aluminum pot (from Ace

Hardware, I believe). This was surrounded by a floating, highly polished

aluminum cold shield - held off from the active cold pot by small

G10 threaded stubs. Wiring passed through a hermetic connector on

the backside. |

|

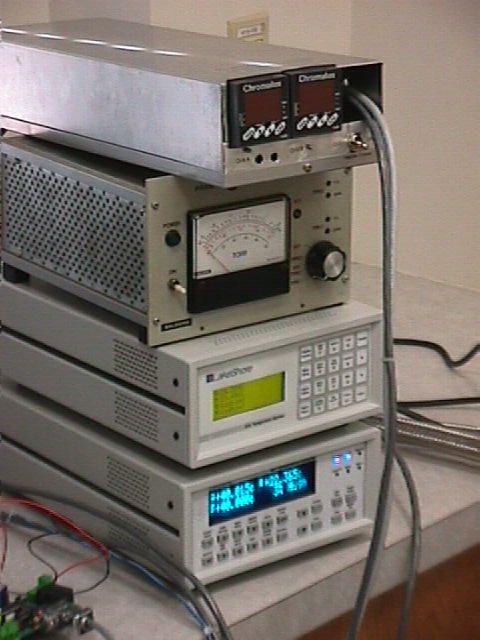

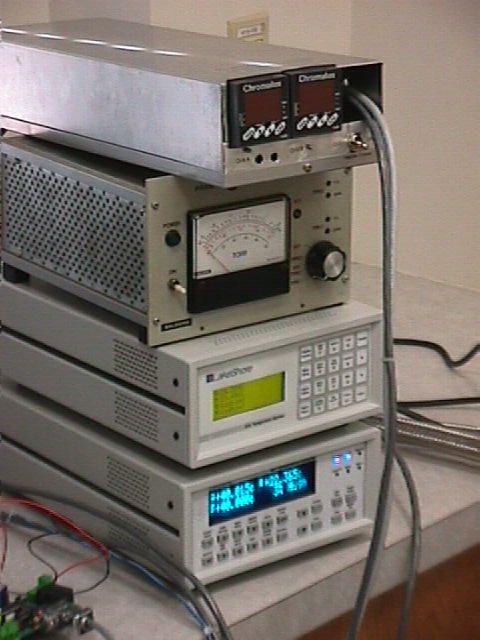

Temperature monitoring and control were provided by a Lakeshore

LS218, a Lakeshore LS 331, and a pair of Chromolux PID controllers.

Thermocouple vacuum monitoring unit is just under the Chromolux pair. |

|

The stepper motor test plate and anodization test plate (with heater)

were placed on G10 standoffs inside the active cold volume. A strap

from the CTI 1050 cold head's second stage (10 K) went to the heater

block and another went from the heater block to the motor plate. In

this fashion, we were able to bring the motors to fixed, stable temperatures

anywhere from 27 to 300 K. Before testing, covers were put in place

and the entire volume vacuum pumped. |

|