|

Dan Eldredge was a graduate student working on the initial

phases of the Mimir project. He developed many of the initial AUTOCAD

design concepts seen in the successful NASA and NSF proposals. He

received a masters degree in astronomy and is employed in industry. |

|

Domenic Sarcia was hired on to be the senior mechanical

designer, engineer, and overall cryogenic expert. During the course

of the Mimir project, he designed over 1,500 individual fabricated

parts, all of the major assemblies, and all test jigs and systems.

He also designed virtually all of the PRISM instrument, employing

many of the lessons learned from the Mimir effort. At the conclusion

of the design and fabrication phase, he left the university to enjoy

the delights of southern Vermont. |

|

To keep costs contained, much of the cryogenics employed

in Mimir was "pre-owned" (to borrow a term) and refurbished.

Where else but in the Boston area could one locate a "Cryogenics-R-Us"

store to outfit a new lab? Here we see the CTI 1020 air-cooled helium

compressor, still on its shipping pad, as it came into the BU lab. |

|

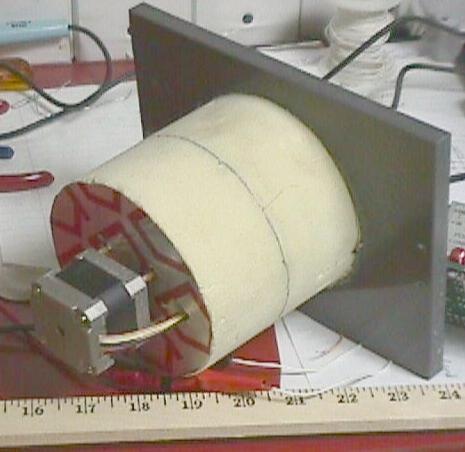

One early idea involved avoiding expensive, special

"cryovac" motors and controllers and instead to use conventional

(inexpensive) stepper motors and controllers. Here we see a stepper

motor wired to a Pontec single-board stepper motor controller. |

|

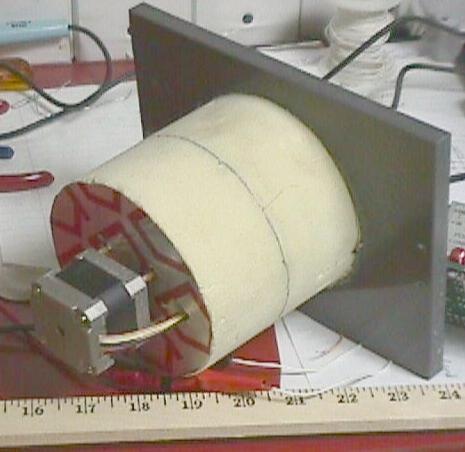

To test whether the stepper motors would work, we first

degreased them, then plunged them into liquid nitrogen (T=77K) to

test their operation. The gray plate holds another simple stepper

controller and sits atop a LN2 dewar. The brown shaft coming from

the center of the gray plate is a fiberglass-epoxy shaft connected

to the stepper motor. Seeing the shaft turn when the motor was submerged

in LN2 was proof that the motor functioned. |

|

This shows the mounting of the stepper motor under the

gray plate. The cylindrical foam plates help reduce LN2 boiloff during

testing. We ran motors for hours, with many starts and stops, with

no failures. |